We are machining aluminum CNC parts regularly. It is lightweight, easy to cut, and fast, but when you do it right. If you choose the wrong machining setup, then it’s costly and slow.

Aluminum is softer than steel, but it changes fast with tool geometry, feed, and coolant. Get the setup right and you save tools, cut time, and the finish looks better.

This guide covers five areas where small changes lead to big improvements.

Each tip is not theory, it comes from real factory practice.

Choose the Correct Aluminum Alloy Before Machining

Aluminum is not just aluminum. There are grades, and each one behaves its own way on the mill. Some cut smooth and clean. Others gum up the cutter and leave a finish you will not like.

Common alloys and their behaviour:

- 6061 – General-purpose alloy. Good all-around. Cuts nice, holds size, runs well with different feeds and speeds

- 7075 – High strength, common in aerospace. Cuts well but needs sharp tools and a solid setup or it will tear.

- 2024 – Tough and wears well, but it will pack the flutes if you do not keep the coolant moving.

- 1100 – Very soft, almost pure aluminum. Smears when it gets hot. Keep the cuts light and edges sharp.

Why this matters for efficiency

The wrong alloy can eat tooling and waste time. If the part does not need the strength of 7075, do not use it. 6061 will run faster and cost less to machine.

Shop-floor tip:

Always keep a small sample block of each alloy. Test drill and cut on the actual machine before production. This will prevent being surprised halfway through production.

Use Tool Geometry Designed for Aluminum

Aluminum will cut fast, but only if the cutter is right. Get it wrong, you will hear the squeal and see the finish go bad. The wrong tool can double the cycle time.

Key factors for aluminum tooling:

- High rake angle – A sharp edge bites into the metal. It slices. It does not rub.

- Polished flutes – Chips slide out. No welding on the edge.

- Chip gullet size – Aluminum makes big curly chips. Give them room or they will jam.

- Uncoated and polished coatings – TiB2 keeps the aluminum from sticking. Bare carbide works fine too.

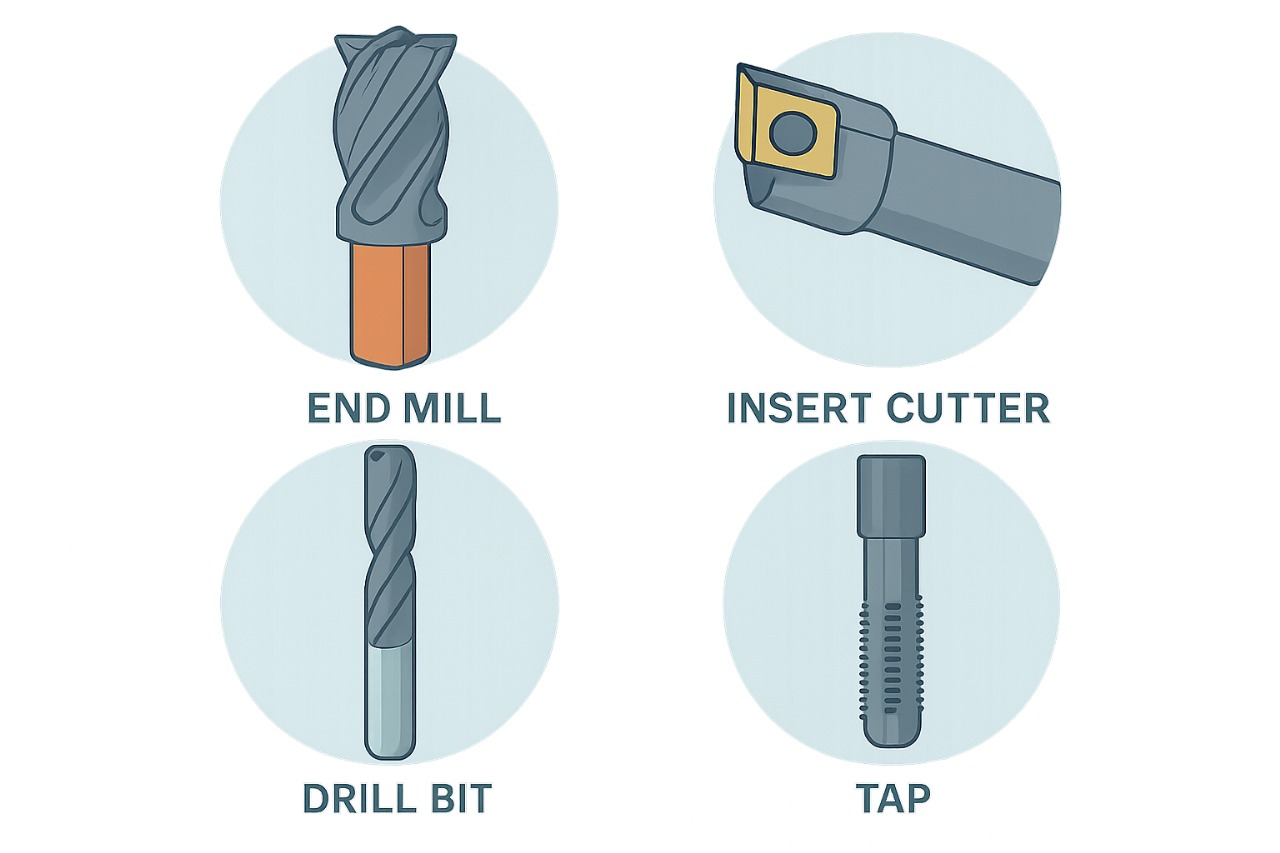

End mills and inserts:

On end mills, go with 2 or 3 flutes for more chip room. For inserts, pick the ground, mirror-polished type. Leave rough-pressed inserts for steel.

Shop-floor tip:

Rub your fingernails on the new cutter edge. If it bites, the cutter is sharp. If it feels smooth, it is dull and will slow your machining.

Control Speeds, Feeds, and Depth of Cut

Yes, Aluminum can handle high speed, but that does not mean max RPM is always best. You get real efficiency when the speed, feed, and depth of cut all work together.

Carbide End Mill Starting Points (6061 Aluminum)

| Cutter Diameter | SFM | RPM | Feed per Tooth (FPT) | DOC (Roughing) | DOC (Finishing) |

|---|---|---|---|---|---|

| 0.25" | 800 | ~12,000 | 0.003" | 0.125" | 0.025" |

| 0.50" | 900 | ~7,000 | 0.005" | 0.250" | 0.050" |

| 1.00" | 1000 | ~3,800 | 0.008" | 0.500" | 0.100" |

Shop-floor tip:

Listen close to the cut. If it’s a smooth hiss, chips are moving right. If it squeals, then it’s rubbing. Hammering means chatter – back off the depth or lock things down tighter.

Manage Heat and Chip Evacuation

Aluminum is good at conducting heat, but heat still builds fast when chips do not clear. That heat causes built-up edge on the cutter and poor finish.

Coolant strategies:

- Flood coolant – Works for most parts. Keeps chips moving away from the cut.

- Mist or air blast – Best for high-speed finishing where coolant could cause thermal shock.

- Minimum quantity lubrication – Reduces mess and gives lubrication directly at the cut.

Chip control:

- Use higher feed to break chips shorter.

- Program retracts to clear pockets before re-entering.

- Never let chips pile around clamps or fixtures – they will scratch parts and throw off alignment.

Shop-floor tip:

If you see silver streaks on your tool shank, chips are rubbing against it. Increase clearance or change tool length to keep the shank above the cut.

Plan the Process for Fewer Setups

Every extra setup costs time and risks. The fastest way to machine aluminum is to design the process so each part stays in the fixture as long as possible.

Fixture Strategies:

- Modular fixturing – Swap parts without re-zeroing.

- 4th-axis fixtures – Machine multiple faces without reclamping.

- Vacuum tables – Hold thin plates without distortion.

Shop-floor tip:

Keep a laminated setup sheet by the machine. Include clamping order, torque specs, tool numbers, and offsets. This cuts down operator questions and keeps cycles consistent.

Troubleshooting Common Aluminum Machining Problems

| Problem | Cause | Fix |

|---|---|---|

| Poor finish | Dull tool, wrong feed | Sharpen/replace tool, increase feed slightly |

| Chip welding | Too slow feed, wrong coating | Increase feed, use polished/TiB2 coating |

| Chatter | Low rigidity, too deep cut | Reduce DOC, tighten setup |

| Burrs | Tool dull, too small feed | Replace tool, adjust feed |

Final Notes

We get the best results in aluminum when we mix speed, sharp tools, good chip control, and smart setups. A machinist listens to the cut, checks chips often, and keeps things steady.

If you want parts that run fast, meet tolerance, and pass inspection the first time,

Request a Free Quote Today