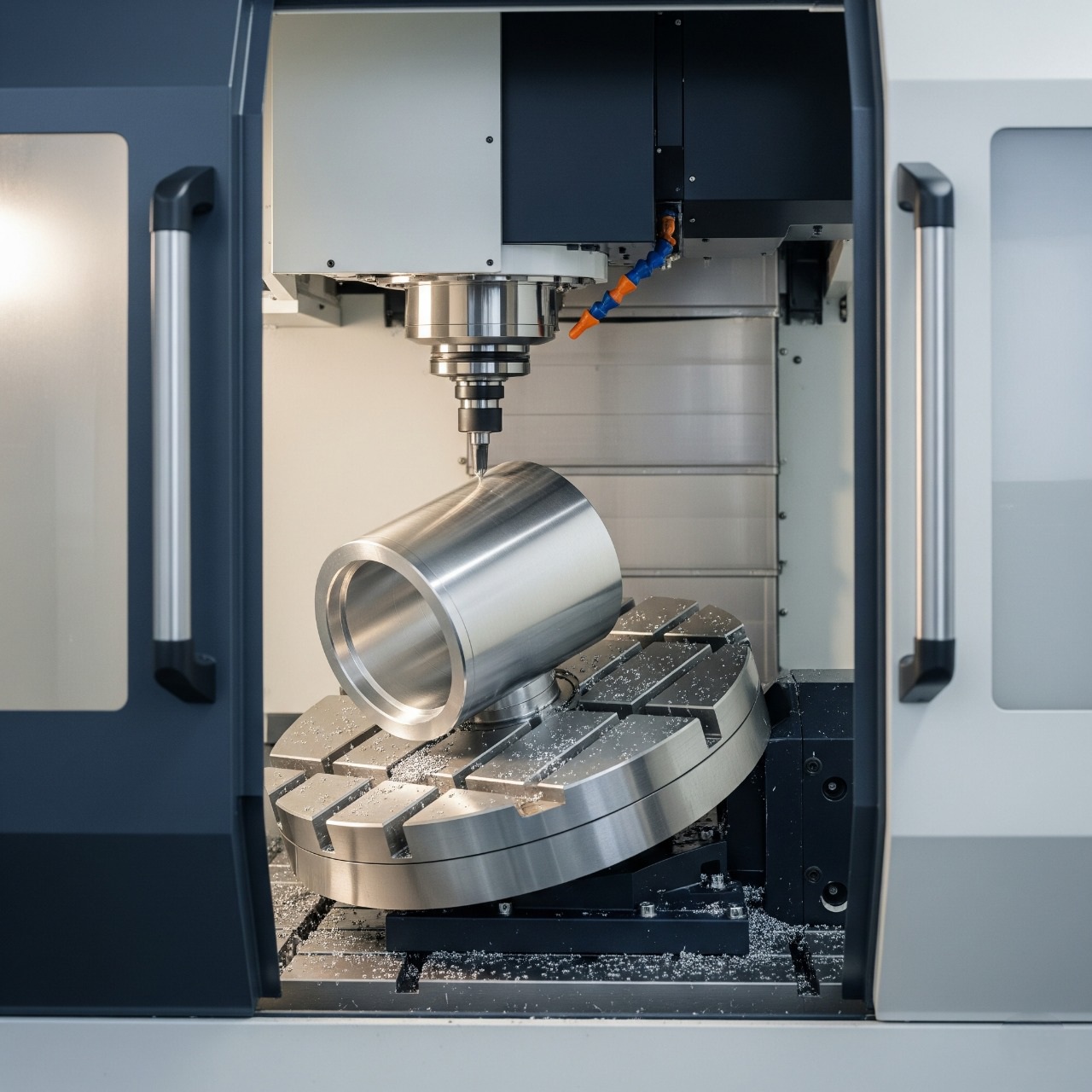

Custom OEM CNC Machined Parts

We manufacture custom CNC machined parts in-house using CNC turning and milling. CNC parts are produced from raw material based on customer drawings and OEM requirements.

Our focus is on custom and repeat CNC components, not standard catalog parts. We support prototype samples, batch production, and repeat OEM supply for industrial customers, typically in brass, aluminum, bronze, copper, steel, and stainless grades.

We supply CNC machined OEM components to customers in the USA and across European markets including Germany, France, and Italy. International shipments are handled as per agreed Incoterms.

Request Quote Today for Custom CNC Parts

CNC Machined Parts – Quick Specs / Snapshot

| Specification | Details |

|---|---|

| CNC Processes Supported |

CNC Turning CNC Milling (3-axis) CNC Milling (4-axis indexing) 5-axis positioning (non-simultaneous) Secondary machining (manual / semi-automatic) |

| Typical CNC Work Scope |

Rotational and milled OEM components Parts requiring turning, drilling, threading, and milling operations Custom OEM machined components |

| Materials Supported |

Aluminium (6061, 6063) Stainless steel (304, 316, 202) Mild / carbon steel (EN8, EN1A, C45, IS 2062) Brass (C36000, C26000, C46400) Copper (C11000) Bronze (PB1, SAE 660) Or as per customer drawing |

| Turning Capacity | Diameter range: 5 mm to 180 mm Length depends on part geometry |

| Milling Capacity | Compact to medium-sized CNC milled parts |

| Typical Machining Tolerance | General machining tolerance: ±0.1 mm Tighter tolerances reviewed case by case |

| Surface Finish |

As specified by customer Anodizing for aluminium Chemical cleaning for brass Mandatory washing for steel Additional finishes via partners |

| Inspection & Documentation |

Vernier / digital calipers, height gauge, Go/No-Go gauges, thread gauges Material test reports / mill heat certificates on request CMM and profile inspection via partners |

| Production Volume |

Prototype / sample before batch (1–10 pcs) Medium and repeat OEM production preferred Standalone very small CNC orders (10–50 pcs only) not supported |

| Drawings Accepted | STEP (3D) + PDF preferred DXF / DWG for simple parts |

| Tooling Ownership | All tooling and fixtures are customer-owned Tooling is never reused for other customers |

Our Recent OEM Custom CNC Machined Parts Production

Custom EN31 Steel CNC Turned Shaft

OEM long CNC-turned EN31 steel shaft with a stepped profile and pointed end, manufactured using precision CNC turning for heavy-duty testing applications requiring high strength and wear resistance.

CNC Milled Bronze Part for OEM Applications

CNC-milled bronze component with drilled mounting holes and a precision machined profile, manufactured using high-accuracy CNC milling for OEM mechanical and industrial assemblies.

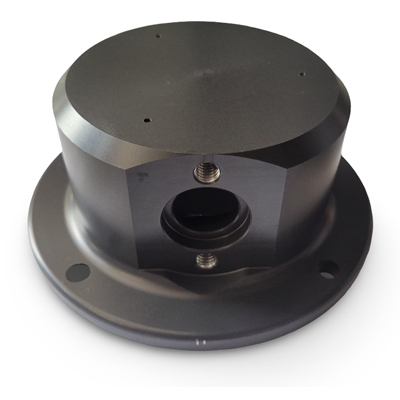

OEM CNC Milled Aluminum Mounting Bracket

Custom CNC-milled aluminum mounting bracket with a precision bore and black anodized finish, manufactured using precision CNC machining for reliable OEM mounting applications.

Custom Brass CNC Turned Part Sleeve for OEM Applications

Brass CNC-turned component sleeve with a stepped body and precision-machined flange, produced using high-precision CNC turning for custom OEM mechanical applications.

OEM Copper CNC Turned Part Sleeve for Mechanical Assemblies

OEM CNC-turned copper sleeve with a stepped profile and precision internal bore, manufactured using precision CNC turning and used as a custom sleeve component in mechanical and industrial assemblies.

Large Custom CNC Machined Aluminum Component for OEM Use

OEM CNC machined aluminum component manufactured using combined turning and milling operations, featuring precision boring and drilled holes, produced with high-precision CNC machining for accurate OEM assembly requirements.

CNC Machining Processes We Perform

We perform CNC turning for round and cylindrical turned components. Turning is used for shafts, bushings, sleeves, spacers, flanges, nipple, adapters, and similar CNC turned parts, typically from 5 mm to 180 mm outer diameter.

CNC milling is used to machine flat surfaces, slots, pockets, holes, and profiles. Most milling work is performed using 3-axis and 4-axis machining for prismatic parts.

Parts that require both turning and milling are processed in multiple steps. Turning is usually completed first, followed by milling operations in a separate setup.

4-axis machining is mainly used for indexed operations where parts are rotated and machined in steps. 5-axis machining is supported for positioning and multi-face access, not for complex simultaneous contour machining.

Typical machining tolerance for standard CNC parts is ±0.1 mm, depending on material and feature geometry.

Manual secondary operations are used where required after CNC machining. These include tapping, threading, chamfering, deburring, and post-machining drilling.

Materials Supported for CNC Machining

Materials are selected strictly as per customer drawing and specification. As an OEM component manufacturer, we machine industrial grades used in regular production.

Aluminum Alloys

Common aluminum grades such as 6061 and 6063 are machined. 6063 is typically used for extruded profiles and non-load-bearing parts, while 6061 is used for general aluminum CNC machined components. Typical applications include neutral bars, blocks, spacers, plates, and lightweight structural parts.

Stainless Steel

We machine stainless steel grades including SS 304, SS 316, and SS 202. These grades are commonly used for shafts, sleeves, fittings, couplings, and corrosion-resistant components.

Mild and Carbon Steel

Mild and carbon steel grades such as EN8, EN1A, C45, and IS 2062 are commonly machined. Typical parts include shafts, pins, spacers, support blocks, and general industrial components.

Brass and Copper Alloys

Grades such as C36000, C26000, and C46400 are machined for brass turned part and milled parts. Common applications include fittings, brass flanges terminals, connectors, inserts, and flanges.

Copper grades such as C11000 are machined for electrical and industrial components. Parts include terminals, connectors, contact parts, and solid copper blocks.

Bronze

Bronze grades such as PB1 and SAE 660 are machined for selected applications. Typical parts include bushings, wear components, and bearing-related parts.

Plastics

Plastics are not CNC machined as standalone parts. Accessories such as O-rings, seals, washers, and gaskets are supplied through partners when required with metal components.

Raw material is sourced from approved external suppliers based on customer specifications and drawings.

Typical CNC Machined Parts We Produce

We manufacture CNC machined parts that are used as functional components in larger assemblies. These parts are custom-made and supplied for OEM production programs. All CNC machining parts are supplied with required finishing as per customer specification.

Common CNC machined parts include shafts, bushings, sleeves, spacers, and milled blocks. These components are typically used for alignment, support, rotation, or load handling in mechanical and electrical assemblies.

Electrical components such as neutral bars and terminals are produced from solid metal bars. Operations mainly include cutting, drilling, and threading based on customer drawings.

Parts are supplied as prototype samples, batch production, and repeat OEM components depending on project requirements. We do not supply standard catalog items.

Tooling and machining fixtures developed for CNC parts are dedicated to the customer and are not reused for unrelated projects.

CNC Machining Size and Capacity

We machine small to medium-sized CNC components based on part geometry, material, and machining requirements.

For CNC turning, CNC turned parts with outer diameters ranging from 5 mm up to 180 mm are supported. Turning length and feature complexity depend on part design and material.

CNC milling is used for compact to medium-sized CNC milled parts used in general industrial and OEM applications.

Machining capacity is reviewed on a case-by-case basis based on customer drawings and material specifications.

Machining is done to general industrial tolerances. Typical tolerance is ±0.1 mm unless otherwise specified on the drawing. Final tolerance capability depends on part design, material, and feature type.

Surface Finish and Post-Processing

All surface finishing and post-processing are carried out through qualified partner facilities. Parts are normally supplied with a finished and cleaned surface condition as specified by the customer.

Aluminum parts are commonly anodized. Brass parts typically receive chemical cleaning to remove surface oxidation. Steel parts undergo mandatory washing and cleaning before dispatch.

Additional finishes such as powder coating, bead blasting, brushing, polishing, and plating are supported based on customer specifications. Finish type is selected according to part function and application.

Deburring and chamfering of machined edges are mandatory for all CNC machined parts. Laser marking for part identification is supported as a post-processing option.

Volume Support and Production Strategy

Prototype parts are supported before full production. Typical sample quantity ranges from 1 to 10 pieces for testing and approval.

Small batch production is supported when it is part of a defined development and validation stage. Standalone low-volume production orders in the range of 10 to 50 pieces are generally not supported.

Our focus is on medium-volume and repeat CNC production for OEM customers. Blanket orders and scheduled repeat supplies are preferred.

High-volume CNC production is supported for repeat parts with stable designs and regular order schedules. Production volume is reviewed on a case-by-case basis based on drawings, material, and order frequency.

Inspection and Measurement Capability

Inspection is carried out at multiple stages to ensure parts meet drawing requirements. Dimensional checks are performed using vernier and digital calipers, height gauges, Go/No-Go gauges, and thread gauges.

Material verification is supported through material test reports and mill heat certificates provided by the raw material supplier, when required.

Basic dimensional inspection reports are provided on request. Profile inspection and CMM measurement are supported through qualified partner facilities when specified by the customer.

Inspection methods and reporting levels are defined based on drawing requirements and order scope.

Industries Served

Electrical and Power Equipment

We machine CNC components such as neutral bars , electrical terminals, threaded connectors, and contact blocks. These parts are used in electrical panels, power distribution systems, and equipment assemblies.

Industrial Machinery and Equipment

CNC machined parts include shafts, bushings, sleeves, spacers, flanges, and support blocks. These components are supplied for industrial machines and OEM equipment assemblies.

HVAC Systems and Equipment

We supply CNC parts such as shafts, bushings, flanges, couplings, and machined flare fittings. These components are used in HVAC units, fans, blowers, and related equipment.

Pipe Fittings and Fluid Handling Components

CNC machining is used for brass and steel pipe fittings, threaded adaptors, couplings, and flanges. Parts are produced as per customer drawings for fluid handling applications.

General OEM Industrial Components

Custom CNC machined parts are produced strictly as per customer specifications. These components are supplied for repeat OEM production across various industrial applications.

CNC Order Lifecycle

The process starts with receipt of the RFQ and customer drawings. Drawings are reviewed and any technical clarifications are discussed before quotation.

A quotation is issued with pricing and indicative lead time. A sample is produced when required before batch production.

After sample approval, CNC machining and secondary operations are carried out. Surface finishing and post-processing are completed through partner facilities when specified.

Parts undergo inspection based on drawing requirements and agreed inspection scope. Final packing and dispatch are completed as per the confirmed shipping method.

CNC Machining Part FAQs

1. What file formats do you prefer for CNC machining RFQs?

We prefer STEP (3D) files along with PDF drawings. For complex CNC parts, a 3D file is mandatory. DXF and DWG files are also accepted for reference.

2. What information should be included in an RFQ?

A clear RFQ helps avoid delays during quotation. Please include material, quantity, surface finish requirement, delivery timeline, and drawings. Repeat or blanket quantity details are recommended when applicable.

3. Do you support prototype or sample production?

Yes, prototype or sample parts are supported before batch or full production. Typical sample quantities range from 1 to 10 pieces for testing and approval.

4. Do you accept very small CNC orders?

Standalone CNC orders with very low quantities such as 10–50 pieces are generally not accepted. One-time orders may be considered if the quantity and part scope are suitable for CNC production. Our focus is on repeat and medium-to-high volume OEM components.

5. How are surface finishes handled?

Surface finishing is applied strictly as per customer requirements. Finishing and post-processing are coordinated through qualified partner facilities.

6. Are inspection reports and material certificates available?

Yes, part inspection reports and material test reports are provided on request. Advanced inspection such as CMM measurement is supported through partner facilities when required.

7. Who owns tooling and fixtures developed for CNC parts?

All tooling and machining fixtures developed for a CNC part are owned by the customer. Tooling is never reused or shared with other customers.

8. How are drawing changes handled?

If the drawing changes, the quotation is revised accordingly. Any impact on pricing or lead time is communicated before production.

9. What shipping terms do you support?

Customer pickup is allowed. Standard Incoterms such as EXW, DAP, and DDP are supported based on agreement. Shipping responsibility and cost are defined at the time of order confirmation.

Request a CNC Machining Quote

To request a CNC machining quotation, send your STEP (3D) file along with a PDF drawing and RFQ details.

Please include:

- Material specification

- Quantity requirement (one-time, repeat, or blanket order)

- Surface finish requirement

- Critical dimensions and tolerance requirements

- Required delivery timeline

- Shipping terms (EXW, DAP, or DDP)

After receiving your RFQ, drawings are reviewed and any technical clarification is discussed if required. A quotation is issued with pricing and indicative lead time before production.