Aluminum CNC Machining Service in USA

We manufacture Aluminum CNC parts that are used in real assemblies, not just prototypes.

From mass production orders for EU automation companies to tight tolerance housing jobs for USA OEMS,

our parts are cut, finished, checked, and shipped without drama.

If you need custom aluminum CNC machining service in the USA and Europe, this page is built for you

Get a Free CNC Quote - Fast Response, Competitive Pricing

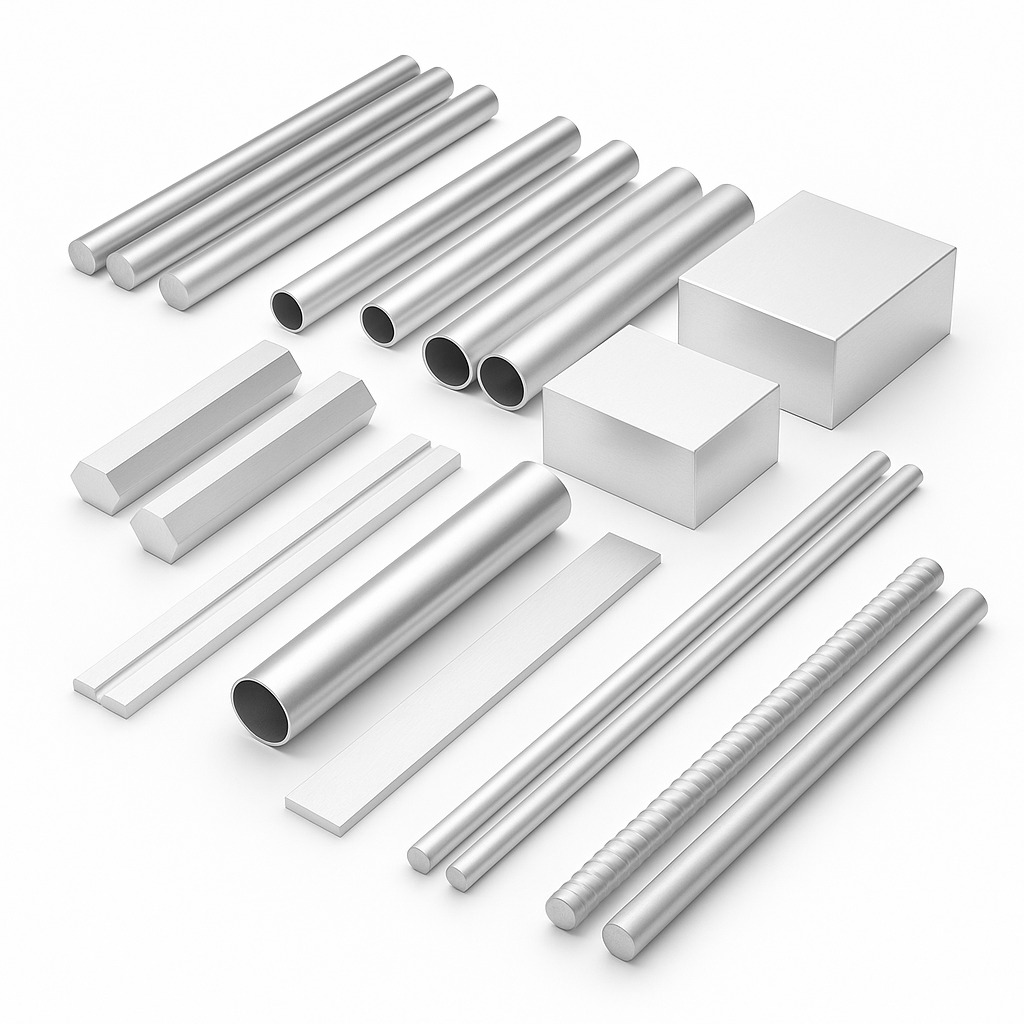

What is Aluminum CNC Machining

Aluminum is not just light weight metal. Aluminum CNC machining is the process of cutting, drilling, turning, and milling operations using CNC machines.

Aluminum is soft for machining and corrosion-resistant, and holds tight tolerances. That is why our so many our customers prefer aluminum over other metals for CNC turning parts and milled parts.

We use CNC turning, VMC milling, and 4-axis setup to deliver aluminum parts. Our products hold form, function, and an excellent finish.

From aluminum raw material bar to complete assemblies, every step is handled in house.

Finishing Options for CNC Machined Aluminum Parts

We provide a different type of options for finishing aluminum parts. Before packaging, your product is cleaned, coated, and protected.

Common finishes for aluminum CNC parts:

- Bead blasting (matte texture)

- Natural clean finish (deburred, solvent cleaned)

- Clear anodizing (Type II)

- Black anodizing (cosmetic and functional)

- Hard anodizing (Type III)

Every batch is checked for thickness and appearance according to specifications of the product drawing.

Why Use Our Aluminum Machining Service in USA

We are not traders and third-party agents. Our factory is located in India—ISO, CE, and ROHS certified. We have been supplying aluminum CNC machining services in USA and Europe since 2011.

What makes our factory reliable for aluminum CNC machining in USA:

- Full in-house CNC turning, milling, drilling

- Fixture repeatability for high volume production batches

- CAM-based programming saved for repeat orders

- Batch inspection with tolerance reports

- Fast quoting, competitive pricing, export packaging

We have shipped aluminum parts to USA for control panel makers, and to UK for OEMs needing repeatable quality and no customs issues.

Our CNC Capabilities for Aluminum Jobs

Whether you are ordering 1000 parts or 10,000, we run aluminum batches using locked-in setups and CAM-verified programs. Every repeat job gets a saved toolpath and fixture file.

We machine:

- Aluminum CNC turning parts (shafts, flanges, rings etc)

- Aluminum milling parts (housings, plates, brackets)

- Custom CNC parts with tight profiles, slotting, as per requirements

- Multi-axis operations for parts with angled or compound features

Machines include:

- CNC turning with live tooling

- 4-axis and 5-axis milling

- Bar-fed lathes for small-to-medium volumes

- Custom jigs and soft jaws for part stability

Products Made with Aluminum CNC Machining

Our aluminum CNC machining service supports high-volume and custom OEM jobs across industries.

Typical aluminum CNC parts we produce:

- Mounting brackets for EV systems

- Enclosures for telecom

- Heat sinks and plates for electronics

- Brackets

- Machined covers and caps with fine threading

- Bushing

- Drone frames and light UAV components

- Custom jigs and fixtures for automation lines

- Adapters

- Neutral bar for panels

We can manufacture your custom part as per product drawing. We offer support for .STEP, .IGES, PDF, and physical sample-to-drawing conversions.

Advantages of Aluminum Machining

Compared to steel and brass, aluminum machining brings clear benefits:

| Property | Aluminum | Brass | Steel |

|---|---|---|---|

| Machinability | Easy | Good | Tougher |

| Weight | Light | Heavy | Heavy |

| Surface Finish | Anodize, chem film | Polishing only | Plating needed |

| Thermal Conductivity | High | High | Low |

| Cost per part (in mass) | Lower | Medium | Higher |

For parts that do not require extreme hardness and magnetic characteristics, aluminum machining is the best for both cost and performance.

Tolerances & Thread Class

We hold tolerance by process not by assumption. Every fixture and tool is verified before production start.

Typical tolerances:

- Milled: ±0.010 mm

- Turned diameters under 40 mm: ±0.05 mm

- Flatness: 0.3 mm per 100 mm

- Thread class: 2A/2B (inch), 6H/6g (metric)

- Thread depth tolerance: ±1 pitch

We record tool offsets and probing data for each job to ensure the next batch starts right where the last one ended.

Material Grades We Machine

We stock and machine the following aluminum grades:

| Grade | Properties | Common Use |

|---|---|---|

| 6061-T6 | General purpose | Covers, housings, brackets |

| 6082-T6 | Higher strength | Frames, plates, and structural parts |

| 7075-T6 | Aircraft grade | Load-bearing, drone parts |

| 2024-T351 | Fatigue resistance | Connectors, clamps |

Mill test certificates (MTCs) are provided upon request. We only buy certified material with traceability.

Packaging & Export Handling

Every shipment is packed for export - no scratches, no corner hits, no open threads.

Our packaging process includes:

- Multi-layer trays with part count labels

- Protective sleeves and plastic caps for threads

- Heat-sealed pouches for critical dimensions

- Barcode and PO sticker labels by box

We also handle ROSH compliance certs, mill test reports, and dimensional reports with every shipment, if requested.

Our Recent Work

We once had an Indiana, USA-based OEM client change the screw color style for the aluminum neutral bar product due to new demand in an ongoing order. We accept his new requirement and change the color of screw zinc plated to blue. And shipped an updated batch next week. That is the difference when you work in your own factory.

Applications We Serve

Our aluminum CNC machining service in USA and Europe supports OEMs in:

Industries we supply:

- Telecom and antenna systems

- EV and battery housing

- Solar mounting systems

- Automation jigs and clamps

- UAV and aerospace tooling

- Medical mounts and guides

We design packaging for bulk shipping — trays, bubble wrap, sealed units — and label with PO and part ID per carton.

FAQ - Aluminum CNC Service in USA

Q1: What is your MOQ for aluminum CNC parts?

100 pcs minimum, but we mostly support 500 to 10,000 pcs production cycles.

Q2: Do you offer anodizing for threaded parts?

Yes. We either mask threads or re-tap them post-anodize, depending on your requirement.

Q3: Do you reverse-engineer or only work from drawings?

We prefer 2D/3D CAD, but we have reverse-engineered legacy parts with no drawings but samples required.

Q4: What aluminum grades do you machine?

6061-T6, 6082-T6, 7075-T6, 2024-T351 — all sourced with certs.

Q5: Do you ship to both USA and Europe?

Yes, we regularly ship to California, Texas, UK, Germany, and Netherlands with full documents.

Request Aluminum CNC Quote - No Delay, No Excuses

If you need aluminum CNC machining service in USA or Europe and care about tolerances, finishes, and real accountability - send us your drawing.

Get a Free CNC Quote - Replies in 4 Hours Or email us your RFQ. We respond fast, ship on time, and machine parts that fit.