CNC turning parts are important components in today’s market. They are precision parts made by rotating a metal piece on a CNC lathe while a cutting tool shapes it. Shafts, bushings, spacers, adapters, and fittings are common examples. These parts are mostly used in machinery, electronics, and industrial assemblies.

We manufacture custom CNC turning parts from brass, aluminum, steel, copper, and other materials as per requirements. Each and every part according to your product drawing, and checked with high QC.

Our major customers are bulk buyers, OEMS, distributors, and manufacturers. They rely on us for high-volume production with consistent quality and a competitive price. We also accept small batch and medium volume urgent orders.

From simple to complex CNC turned parts, every piece is made with precision and tight tolerances.

We ship to the USA, Europe, and across the globe, helping buyers to receive accurate parts on time.

Get a Free CNC Turning Parts Quote – Send your drawing

We use a range of metals to produce turning parts. Here are a few we commonly work with,

Brass is valued for machinability, durability, and corrosion resistance. It is often used in fittings, connectors, valves, and precision components. Brass is easy to machine, which makes it ideal for both prototype runs and large-scale production.

Aluminum is lightweight, easy to shape, and a cheap metal. It is widely used for automotive components, heat sinks, housings, and industrial parts. Aluminum parts are good when weight and price are major concerns. It also gives a smooth finish and resistance to corrosion.

Steel has many alloys, such as stainless steel, carbon steel, and mild steel. Steel is a strong and wear-resistant metal. Common parts are shafts, bushings, gears, and heavy-duty mechanical assemblies. Stainless steel provides corrosion resistance, and carbon steels provide strength and durability. Steel is best for durability and under critical conditions.

Copper offers excellent electrical and thermal conductivity. It is commonly used for electrical connectors, heat exchangers, grounding components, and specialized industrial parts. Copper can also be combined with other metals, like brass, for better electrical conductivity.

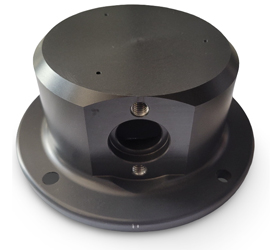

Brass CNC-turned component sleeve with a stepped body and machined flange, produced for custom OEM applications.

Custom CNC-turned INOX A2 (304) stainless steel hex stud with M8 × 1.25 external thread and hex flats.

OEM Long CNC-turned EN31 steel shaft with stepped profile and pointed end for heavy-duty testing applications.

OEM CNC-turned copper sleeve with stepped profile and internal bore.Used as a custom sleeve or spacer component in mechanical and industrial assemblies.

Custom CNC-turned brass component with external threads, machined flange, and as-turned surface finish.

Custom CNC-turned brass stud with 5/8-24 UNF external thread, M3 × 0.5 mounting hole, and nickel-plated finish.

Automotive manufacturers use shafts, spacers, and bushings in engines, braking systems, and transmissions. Bulk production is common in this industry, so long-term reliability and consistency are essential.

Electronics require small and precision turned parts such as adapters, connectors, and housings. Brass and copper metals are popular because they provide excellent conductivity and corrosion resistance. Also, these are suitable for large-scale assembly lines.

Steel CNC turned parts are widely used in machinery and heavy equipment. Products like fittings, sleeves, bushing, and hydraulic components must handle pressure, wear, and repeated motion without failure.

General manufacturing industries depend on CNC turning services for tooling, custom spacers, and assembly parts. From 1,000 pieces to high-volume bulk runs, CNC turning ensures accuracy, repeatability, and cost efficiency.

Our CNC turning service supports buyers and OEMs across the USA, UK, Europe, and Asia. We handle both mid-size orders and high-volume production.

Our CNC Parts factory is set up for both small runs and high-volume production. We handle small batches of 500 pieces, as well as bulk quantities production with competitive price, consistency, and tight tolerance. Our machines are tooled for multiple metals, from brass and aluminum to stainless steel and copper, giving buyers flexibility under one roof.

| Capability | Details |

|---|---|

| Minimum Order Quantity | Depends on product drawing and requirements. |

| Maximum Production Capacity | Up to 100,000 pieces per month |

| Supported Metals | Brass, Aluminum, Stainless Steel, Carbon Steel, Mild Steel,Copper, Bronze |

| Tolerance Range | ±0.01 mm |

| Lead Time | 2 - 4 weeks (depending on order size and complexity) |

| Finish Options | Polishing, Plating, Anodizing, Coating |

Spacers create precise gaps between two parts in assemblies. Mostly used in machinery, electronics, and fittings. We manufacture high-conductivity copper spacers and brass spacers for electrical assemblies.

Protect moving parts from friction and wear. Brass, bronze, and steel bushings are widely used in industrial heavy machinery and automotive applications.

Shaft use in engines, pumps, and transmission systems. But needs high accuracy and good finish for reliability.

Machined to connect two different parts. CNC turned adapters are common in fluid handling, hydraulics, and pipe fittings. We specialize in precision brake line adapters and brake line union components that require leak-proof threads. Common examples include hydraulic adapters and brake tee fitting components for automotive lines

Fittings and connectors join pipes and tubes. They are commonly made from brass and SS.

Precision-turned fasteners like bolts, studs, nuts, and rods. Bulk orders are common in construction and machinery supply chains.

Shaft collars act as mechanical stops, locators, and spacers. Used across industrial equipment and automation.

End caps and plugs are used to cover the pipe ends. Available in different metals depending on the application.

Used in electronics, telecom, and automotive. Tight tolerance required for secure connection.

These parts connect and control fluid lines. Used in construction, industrial, and heavy machines.

| Metal | Cost | Strength / Durability | Machinability | Weight | Common Uses |

|---|---|---|---|---|---|

| Brass | Medium | Moderate | Excellent | Medium | Bushings, fittings, electrical contacts |

| Aluminum | Low to Medium | Moderate | Excellent | Very Light | Automotive, aerospace, housings, spacers |

| Stainless / Alloy Steel | Medium to High | Very High | Moderate | Heavy | Shafts, fasteners, heavy machinery |

| Copper | Medium to High | Moderate | Good | Heavy | Electrical parts, spacers, grounding components |

Not any specific MOQ because its custom parts. MOQ depends on buyer requirements and drawing.

Lead time depends on part size and order volume. Most bulk runs ship in 3-4 weeks.

We work with brass, aluminum, stainless steel, carbon steel, mild steel, bronze, and copper.

Yes. We manufacture parts according to your drawing. Send us your CAD file & technical drawing.

Yes. We machine custom diameters, lengths, and threads according to buyer requirements.

Yes. We provide samples, so buyers can test fit and function.

Yes. We regularly ship to USA, Europe, Asia, Middle East, and Africa with complete export documents.

Parts are export-packed in bulk cartons and custom packaging as requested, with anti-rust and safe handling.

Share your part drawing, quantity, and material. Our team will prepare a detailed quotation for you.

CNC turning parts remain one of the most reliable solutions for bulk buyers, OEMs, and manufacturers. We support both small run and bulk quantity orders at a competitive price.

Whether it's brass fittings, aluminum spacers, steel shafts, or copper connectors, we will supply them with strict quality control and on time.

Get a Free CNC Turning Parts Quote – Send your product drawing today