Aluminum CNC parts are used in almost every industry today. From high-performance automotive parts to lightweight components in aerospace and electronics, aluminum remains one of the most demanded materials for CNC precision. We have worked with this metal in real factory floor conditions, and it responds well under every machining operation.

If you are sourcing Aluminum CNC Parts from the USA, UK, Europe, or Asia, our facility can handle bulk orders and tight tolerance machining without delay. Whether it is for high-volume production or one off prototypes, we offer reliable CNC machining services using the right alloys and verified machining techniques.

We have machined aluminum into all types of parts. Not just prototypes or one-offs. Real production. Real loads. Real users.

Cut deep, balanced, and tapped. Often hard coat anodized. We have done these for LED panels, battery packs, and server racks.

Common in aerospace interiors and camera rigs. Often thin. Needs good fixturing.

Tapped holes, soft edges, no burrs allowed. Clean room prepped before packing.

Handle mounts, pedal arms, throttle bodies. Finished smooth or coated matte.

Weight-critical. Often hollow or pocketed. Wall strength matters.

Internal bosses, threading, gasket grooves. Often anodized after machining.These housings often require brass threaded inserts for plastic to ensure secure, repeatable fastening

Sensor holders and motor plates. Often checked for flatness or parallelism.

Test fixtures, jigs, clamps. Built for use, not display.

These are not items you find online. These are jobs built for actual machines and actual assembly lines. Every part goes through operator checks before boxing. It is not about volume. It is about doing it right.

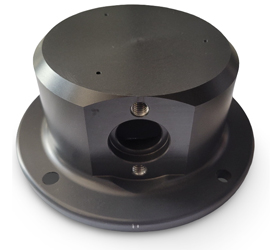

OEM aluminum component produced by CNC milling, featuring a precision-machined bore and black anodized surface finish.

OEM aluminum 6061 component manufactured by CNC machining, featuring milled geometry and precision pocket features.

OEM CNC machined aluminum part manufactured using turning and milling operations, with precision boring and drilled holes.

Custom aluminum 6061 component produced by CNC milling, featuring precision-machined pockets and mounting features.

Different shapes and tolerances call for different machining setups. In our shop, the CNC operations depend on part geometry, material hardness, and finish requirements.

We use:

We also combine machining with deburring, polishing, and surface treatments to get the final component ready to use.

For specialized fluid systems, we also offer copper tube bending to complement our machined blocks

Finishing is where aluminum gets its final job done. You cannot skip it. A raw part may look fine today but will corrode or wear out in real use. We offer only finishes we have run ourselves. No catalog promises here. These have been tested on real jobs with real tolerances.

Good for wear and corrosion. Makes parts stronger on the surface. We run type II and type III anodizing. Bath time and load spacing matter. Overcrowd the rack, and parts come out blotchy. We know. We have fixed it.

Takes off machine marks. Leaves a dull, even look. Used a lot for handles and casings. We control air pressure and media grade to avoid softening corners.

Color with durability. Not just cosmetic. We pre-bake parts to avoid gas-out and then apply full coverage. We often coat parts that will live outdoors.

For part numbers, logos, or trace codes. Works best after anodizing. Etch depth matters when parts face wear.

Some jobs want that clean visual touch. We finish by hand or wheel depending on request.

We match finishes to function. You do not anodize a sliding pin the same way you treat a bracket that just bolts down. Each one is handled based on how it will be used. That is not just a process that is attention.

In the past two decades, we have supplied CNC aluminum parts across a wide range of industries. Each has its own drawing, alloy, and tolerance requirement.

We have delivered brake levers, engine brackets, sensor housings, and valve covers in 6061 and 7075 aluminum.

Wing ribs, seat frames, and mounting blocks for aircraft cabin systems. Aerospace needs high strength with reduced weight.

Heatsinks, laptop frames, connector housings. Aluminum is good for thermal and electrical use.

Small batches of precision components for surgical equipment and diagnostic machines.

Rust-resistant fittings, clamps, and covers used in fresh and saltwater conditions.

High-quality cnc components require more than just a machine. To deliver reliable results, we focus on extreme tolerance control, repeatability, and superior surface quality for every batch

Precision in CNC work depends heavily on the equipment used, you can explore how specific parts influence accuracy and stability in our guide to CNC machine components.

Each alloy offers different benefits. We help clients pick the right one based on strength, corrosion, machinability, and price.

You can send your specs with an alloy code or ask for a suggestion based on your application. While we specialize in aluminum, we are also leading providers of brass cnc turned parts for applications requiring high conductivity or low friction. We also offer raw material sourcing for full traceability.

Beyond aluminum, we are recognized Brass inserts manufacturers, providing high-strength threads for plastic assemblies.

Aluminum has more than one advantage. It is not just about weight. When handled right, it becomes the material that fits best in cost, function, and finish.

Easier to move. Less strain on equipment. Useful in anything that moves or lifts.

Lower tool wear. Shorter cycles. Higher daily output.

Good for thermal paths. Used in electronics, power units, and battery builds.

Can be anodized, coated, etched, or left raw. Looks clean either way.

With the right finish, it lasts outdoors, near salt, or around chemicals.

Price per part drops fast after the first few runs. Tooling lasts longer. Less spindle time means lower hourly costs.

We have seen all this firsthand. A well-machined aluminum part just works. It does not crack under torque. It does not warp during mounting. It aligns, fits, and holds.

That is what matters.

As global cnc turning parts manufacturers, we ship high-precision aluminum cnc parts to industrial buyers in the United States, United Kingdom, Europe, and Asia. Bulk buyers and OEMs choose our facility for its ability to deliver complex cnc components with fast sampling and honest timelines.

We deliver parts for automotive, defense, and energy sectors. Midwest and West Coast buyers often require anodized and tight-tolerance work.

Small-batch medical components and aerospace support brackets are common.

Germany, France, and Italy prefer 7075 aluminum for robotics and machinery.

Orders often require larger quantities with clear batch marking and labeling.

We provide a professional custom CNC machining service in Italy, where manufacturers and OEMs rely on us for consistent quality, fast sampling, and honest timelines.

We are not just running machines. We are working with actual tolerance-critical parts. That includes inspecting every cut, measuring every bore, and reviewing the drawings before setup.

We handle engineering drawings, 3D models (STEP, IGES), or even sketches. Our team reviews feasibility, toolpath strategy, fixture setup, and finish specs before production.

If you are looking for a reliable source of aluminum cnc parts in the USA, UK, Europe, or Asia, we can deliver fully machined, inspected, and finished cnc components with full material certificates. Tell us your alloy, quantity, and drawing to see how our expertise as cnc turning parts manufacturers can benefit your project.

Get a Free CNC Quote or submit your drawing to start.