Neutral Bar Manufacturer - Custom Machined Brass, Copper, and Aluminum Neutral bar USA, Europe, and Asia

We do not assume hole positions. We manufacture neutral bars that actually work inside a real control panel. We make top quality neutral bar to use in various electrical systems. Whenever you are setting up a power distribution network, control panel, and switchgear to need a neutral bar.

At our factory, we machine custom neutral bars with accurate, spec-matching, precise tolerance and real-world durability. Every bar gets fixture aligned before the final cut. With every batch, it gets torque checked.

Neutral bars carry return current and are typically isolated from the enclosure, while ground bars are used for protective earthing and are bonded to the panel body. This page focuses on neutral bars used in electrical control panels. Ground bars are supplied separately when required.

You want a bus bar that will fit the first time, no bending, no burr, no call-backs. That is exactly what we built.

Types of Neutral Bars - Material-Wise Breakdown

Not all metal bars handle current the same. Depending on the environment, current, and panel design, we machine different types. Each with pros and cons.

Brass Neutral Bars

- Material: C360, CZ121

- Use Case: Domestic panels, small-scale industrial cabinets

- Conductivity: Good (but lower than copper)

- Machinability: Excellent, clean threads, fast cycles

- Corrosion Resistance: Moderate

- Cost: Lower than copper

We ship these across India, UAE, and Southeast Asia for residential and building wiring boxes.

Copper Neutral Bars

- Material: C101 (OFHC) copper

- Use Case: High-load switchgear, solar boxes, rail panels

- Conductivity: Excellent (best choice for current flow)

- Machinability: Fair and clean with sharp tooling

- Corrosion Resistance: High (tin/nickel plating improves it further)

- Cost: Higher

Popular in USA and Europe for solar, EV, and critical electrical panels.

Aluminum Neutral Bar

- Material: 6061, 6082, 6063-T6, 7071

- Use Case: Weight-sensitive panels, transport and modular racks

- Conductivity: Moderate (less than copper, more than brass)

- Machinability: Good and long chip control needed

- Corrosion Resistance: Low (requires surface coating)

- Cost: Lower

Used mostly in bus bar trunking systems, and rail or EV battery housing.

We manufacture as per client’s requirements. We can suggest which material will fit based on your current and enclosure type.

Recent OEM Neutral Bar Production

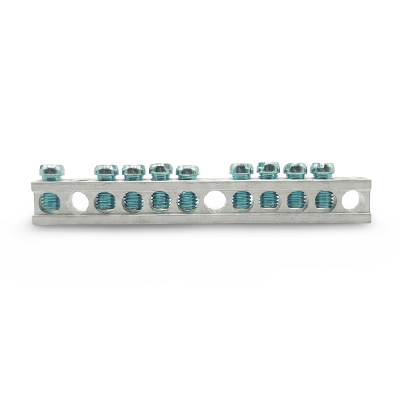

OEM Aluminum Neutral Bar with Multi-Point Screw Terminals

Aluminum neutral bar produced by reverse-matching a customer reference sample. The bar measures approximately 95 mm in length and 12.5 mm in height, with a total of 12 machined holes, including three mounting points. Supplied assembled with blue-coated clamping screws, this neutral link is used for conductor termination in electrical distribution boards and industrial control panels.

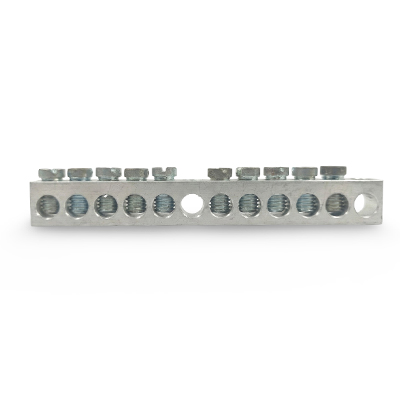

Custom Aluminum Neutral Bar with 12 Threaded Circuit Terminals

Aluminum neutral bar produced for electrical distribution assemblies. The bar has 12 threaded circuit terminals spaced at 10.05 mm intervals. Two threaded mounting holes. Designed to accommodate 2–14 CU conductors, the bar is supplied assembled with combination head screws and is commonly used in panelboards and industrial control cabinets..

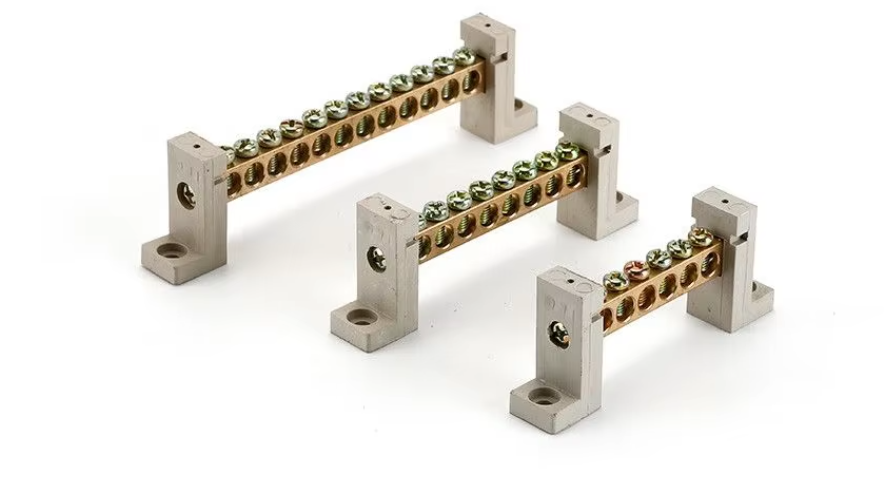

OEM Brass Neutral Bar with 15 Inline M3 Terminal Threads

Brass neutral bar manufactured with 15 inline M3 threaded terminal holes, assembled with MS combination head screws for conductor clamping. The bar includes one large and one small side hole and a uniformly machined brass body, suitable for electrical control panel and distribution assemblies.

Custom Tin-Plated Brass Neutral Bar with 15 M4 Threaded Terminals

Tin-plated brass neutral bar machined with 15 inline M4 threaded terminal holes. The bar has a uniform matte tin surface and precision-machined faces with consistent terminal spacing. Two larger side holes are provided for mounting. This neutral bar is used in electrical distribution boards and control panel assemblies where brass conductivity with a protective tin coating is required.

OEM Long Brass Neutral Bar with 24 Inline Terminal Positions

Long-format brass neutral bar machined from solid brass and left in a raw machined surface condition. The bar includes 24 inline threaded terminal holes along its length and four mounting holes for secure installation. A stepped center section is incorporated into the design. This neutral bar is used in electrical control panels, distribution boards, and OEM electrical assemblies that require a higher number of neutral connection points.

OEM Copper Neutral Bar with Multiple Hole

Copper neutral bar machined from solid copper stock with precision-drilled through holes and cleanly finished edges. The production image shows bars in multiple lengths, indicating custom manufacturing to suit different circuit layouts in electrical control panels and distribution boards.

Comparison Table – Brass vs Copper vs Aluminum Neutral Bars

| Feature | Brass Neutral Bar | Copper Neutral Bar | Aluminum Neutral Bar |

|---|---|---|---|

| Material Grades | C360, CZ121 | C101 (OFHC) | 6061, 6082 |

| Conductivity | Moderate | Excellent | Fair |

| Machinability | Excellent | Moderate | Good |

| Corrosion Resistance | Moderate | High (with plating) | Low (needs coating) |

| Common Use Cases | Domestic, OEM Panels | Solar, EV, Switchgear | Rail, Modular Cabinets |

| Finish Options | Natural, Tin, Nickel | Tin, Nickel, Raw | Tin, Anodized, Painted |

| Thread Quality | Very High | High | Good |

| Cost | $$ | $$$ | $ |

Neutral Bar Types We Machine

We are not limited to one shape or drill style. We are an OEM custom neutral bar manufacturer. Whether you send a step file, a drawing PDF, or one old sample. We make the type that is needed.

- Two-hole neutral bars

- Neutral bar with lug

- Multi point neutral links

- Neutral bars with insulated base

- Tapped bars with captive screw holes

- Chassis-mount and DIN rail compatible

Tolerances We Hold on Neutral Links

We do not leave tolerances up to chance. These are hard specification for us and we hold in production:

- Hole Diameter: ±0.05 mm

- Hole Pitch Spacing: ±0.10 mm

- Bar Flatness: ≤ 0.15 mm per 300 mm length

- Hole to Edge Distance: ±0.10 mm

- Tapped Thread Pitch Class: Metric 6H or UNC 2B (as per requested)

During final QC, we use Go/No-Go gauges, torque drivers, and flat plate checks. If plating is involved then we have to thread undersize and relief chamfer is pre-compensated.

Finishes Available on Neutral Bars

Surface is upon your applications. Some bars need raw finish, others need coating.

We offer:

- Natural brass (degreased and deburred)

- Tin plating (for high-current and corrosion-sensitive setups)

- Nickel plating (marine and telecom rack use)

- Electro polished for copper

- Matte bead-blast finish

- Clear anti-tarnish spray (upon request)

All finishing needs post-work include edge deburring and hole cleaning. For example, plated bars, thread tolerances are pre-adjusted before coating.

How We Check Quality

We run on tight tolerance, real people, real quality checks.

- Visual Hole Layout Check: holes matched against drawing

- Thread Gauge Test: every pole point passes Go/No-Go

- Plating Check: thickness verified if specified

- Flatness Jig Test: bar clamped to verify no warp

- Deburr & Clean Pass: final edge check before pack

- Packaging: anti-oxidation wrap, batch tag, drawing copy included

One OEM shipment in Germany failed flatness by 0.4 mm on early sample testing. We re-levelled the fixture bed, ran dummy tests, and the final lot stayed flat within 0.12 mm. That job still repeats today.

Application Industries

We ship custom neutral bars across USA, UK, Europe, and Asia to real manufacturing environments. No marketing fluff. Just bars that pass fit tests in actual control panels.

- Power Distribution Cabinets

- Electrical Control Panel

- Telecom Racks

- Solar Combiner Boxes

- Switchgear

- Battery Packs & Inverter Panels

- Rail Control Systems

- Marine Panels & Offshore Installations

Our bars go into both OEM assembly lines and field-installed retrofit boxes.

Recent Job Examples from Our Factory

USA – South Bend, Indiana

Manufacture 30000 aluminum neutral bar quarterly, all holes tapped 8mm, 1.95mm spacing, 122mm length tolerance.

USA – Colorado

Supplied 50000 Pieces of neutral bars, CZ121 brass, slotted mount tabs, blind tapped holes with back chamfer.

Saudi Arabia – Telecom Equipment Build

Custom brass neutral bars, nickel plated, 5 mm thick, 1 meter length, exact match to legacy 1990s panel specs.

FAQ

Q1: Can you machine a neutral bar to match our existing panel holes?

Yes. Send the old bar, or just a dimensioned drawing. We reverse measure it and match it hole to hole.

Q2: Do you provide plated and natural versions?

Yes. Most bars are raw brass and copper. Tin and nickel plating available, with finish cert if needed.

Q3: What is your standard hole tolerance?

±0.10 mm. For tighter specs, we can hold ±0.05 mm on shorter bars if fixture allows.

Q4: Can I get thread + Fixer holes in the same bar?

Absolutely. Mixed-hole bars are common. We mark each clearly in drawings and in QC.

Q5: How fast can you ship to the USA?

Samples: 5 to 7 working days. Production: 10 to 15 days typical. Express courier, with tracking and customs support.

Q6: Can I send a DXF and Step 3D model?

Yes. DXF, STEP, IGES, and even a drawing all work. We confirm specs before starting.

Q7: Do you supply material certificates?

Yes. Brass, copper, and aluminum. All come with batch traceability and certs on request.

Get a Free Neutral Bar Quote – Fast Response

Whether you need 1000 bars for a small batch or 1,0000 mass production for a panel line. We machine what fits.

- Manufacture according to your drawing

- Fast machining, real fit accuracy

- Tin/nickel plating if needed

- Batch repeat accuracy every time