Every aluminum neutral bar we ship is manufactured in-house to match your control panel. These are not stock items. No off-the-shelf bars here. Each part is made to your specification hole layout, thread size, mounting face, and surface finish. We run everything under one roof.

We do not stock generic bars. We machine every aluminum neutral link to match your drawing, thread type, and terminal layout. Whether it is for switchgear cabinets, EV chargers, or electrical panels, our bar fits clean, mounts solid, and holds torque. No crack, no spin, no burr. Just parts that drop straight into the application.

Our bars are already used in the USA, Europe, and across globe. One USA client batch had a thread burr caught before packing. We re-ran every hole and hand-checked every thread. Two hours extra, but zero parts failed fit.

At Hiren Brass Products, we machine custom aluminum neutral links that fit your spec exactly. No re-tapping, no filling, no compromise.

Get a Free Aluminum Neutral Link Quote – Fast 4 Hour Response

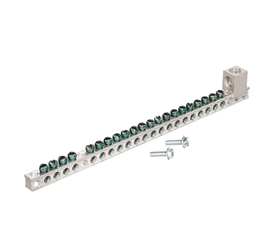

Aluminum neutral bar produced for electrical distribution and control panel applications, manufactured to a length of 4.1275 inches with 13 holes including 10 circuit terminals and 3 mounting holes. Designed to accommodate 14 AWG to 4 AWG conductors and assembled with combination head screws, suitable for panelboard and control cabinet installations.

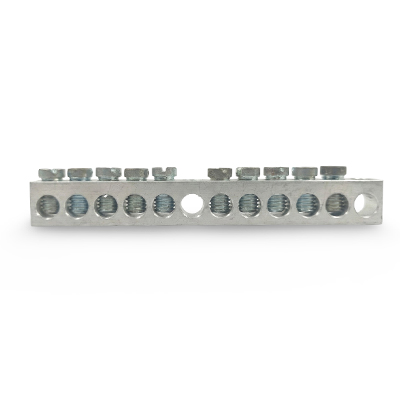

Aluminum neutral bar manufactured for electrical distribution, with 12 threaded circuit holes, and 10.05 mm hole spacing, including two threaded mounting holes. Designed for 2–14 CU conductors and assembled with combination head screws, suitable for panelboard and control cabinet use.

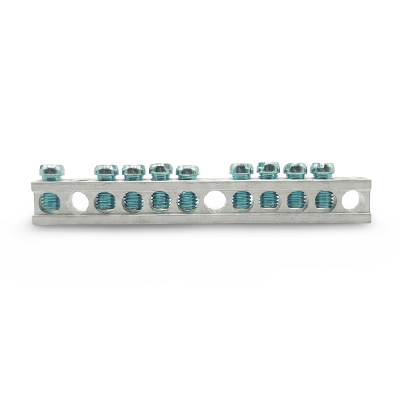

Aluminum neutral bar manufactured from a customer-supplied sample, featuring an approximate 95 mm overall length, 12.5 mm height, and 12 total holes including three mounting holes, assembled with blue-tinted coated screws for conductor clamping. This neutral link is used in electrical distribution and control panel assemblies.

Electrical grade aluminum neutral bar manufactured from Aluminum 6101 and designed with 15 circuit holes to support 14 AWG to 4 AWG copper conductors. The neutral bar is produced with uniform hole spacing and supplied with wire set screw terminals, suitable for use in electrical control panels and distribution assemblies where reliable neutral termination is required.

All aluminum grade have not same property. We do not use generic alloy. Every job is cut from confirmed stock. Grade 6061-T6, 6063, 7075, 6082 According to fit, thread type, and conductivity.

If you are not sure about grade, send us your drawing and application. We can advise materials you that match your environment and current rating.

We do not ship bars that need rework at your end. Our neutral bars are drilled, and aligned to fit your application with perfect tolerances.

For plated parts, we make an undersized thread so that before coating to maintain thread accuracy at post-finish

We machine every type of OEM custom neutral bar. Whether you send 3d step file or a PDF drawing. We cut to fit.

Each order is repeatable . We fixture log every job for your next batch.

Natural finish or raw aluminum corrodes fast. That is why we offer options that keep your neutral bars protected in field conditions.

All finishes get pre-cleaned and post-deburr tested. Threads are either masked during coating or re-taped after finishing.

We are not traders, we do not buy from outside and then ship. We manufacture each neutral bar in-house facility. From start to raw aluminum bar to complete part. Every operation passes through our machines.

Every cut is a dry run and tested. Drill RPM, thread pitch, offset, even deburring, everything.

When the customer places a repeat order, the second batch looks exactly the same as first one. Because the same fixture, CAM path, and check sheet stay with your job ID.

We work with OEMs that need the same bar every month.

Your product, your drawing, your thread type measurements - locked in. We name the CAM file with your PO number. Next time place repeat order, there is no re-check, no re-measure. Just clean output, same as last batch.

One EU solar enclosure client ordered the same 7-hole flat aluminum neutral link every quarter since 2020. We never shifted pitch. Not once.

If you are building panels and wants a vendor that delivers same part, same fit, every time -that is what we do.

We ship aluminum neutral bars globally. That means every batch leaves with:

We already supply to OEMs in Germany, Netherlands, UK, California, and UAE. So customs and compliance is familiar ground.

Need country-specific test reports? Just ask.

We follow QC very strictly for every batch. QC starts before the bar hits the mill.

One batch for a UAE control panel OEM failed plating thickness on the first run. We stopped production, re-sampled with the coating vendor, adjusted back time, and re-sent the complete batch within 1 week. Customer place repeat orders monthly.

Our neutral bars not just spec sheets, they go into field ready products around the words.

If you are looking for lightweight, corrosion-resistant, tapped neutral bars, this is what we make.

Need customs country-specific plating? Let us know. We already supply multiple export-grade jobs every quarter.

Yes. Send dimensions, drawing, or even the sample. We check all diameters and build according to your specifications.

Yes. Common to mix M6 thread with ⌀5.5 clearance holes. You just have to mark them in your drawing.

Only if it is the wrong alloy. We cut in 6061, 6082, and 7075 with thread class control. For frequent terminal changes, we recommend tin plating and steel inserts.

Yes. Tin plating is common. We mask threads and tap after plating for fit retention.

Samples: 5-7 working days.

Production: 10-150 working days depending on finish and volume.

We are Custom OEM neutral bar manufacturers. We can make it according to customer requirements and the drawing.

We make what you need. We fixture and recheck everything. You get neutral bars that fit, hold torque, and survive real-world install.

Get a Free Quote of Aluminum Neutral Bar - most replies in under 4 hour