Brass Inserts Manufacturer - Built to Fit, Machined to Hold

We manufacture custom OEM brass inserts that will work and hold under critical condition. Press-fit, Heat set, molded-in, ultrasonic we have cut thousands of them. Some parts ship to USA, some ship to consumer connectors in Germany and some other may ship to Europe for auto line.

Whether it is a Brass Threaded Insert, Brass Molding Insert, or OEM custom Brass Insert for plastic molding, we cut them with real precision knurl grip, clean thread and tight tolerance. Our inserts are not just good on paper but they work when parts hit the press.

Looking for Brass Inserts that hold and install right the first time?

Request a Free Brass Insert Quote

We serve clients across the USA, UK, Europe, and Asia, supplying tight-tolerance parts that hold up under real world use. Whether you need 10000 piece or 5 million pieces mass production, we are built to deliver.

Brass Inserts – Quick Specs / Snapshot

| Specification | Details |

|---|---|

| Manufacturing Method |

Dedicated automatic brass insert machines CNC turning only for large or special inserts |

| Materials |

Brass C36000 (default) CZ121 and other brass grades on request |

| Insert Types |

Press-in inserts Heat-set inserts Mold-in inserts Inserts suitable for ultrasonic installation |

| Typical Size Range |

Small to medium inserts used in plastic molding (exact limits reviewed per drawing) |

| Thread Types |

Metric (M-series) UNC and UNF threads Blind or through threads as per design |

| Knurl Type | Controlled rolled knurl for plastic retention |

| Dimensional Control |

OD typically around ±0.05 to ±0.10 mm depending on size Roundness controlled around 0.05 mm on critical diameters |

| Thread Control | Go/No-Go gauge checks at regular intervals during production |

| Surface Finish |

Nitric finish as default Brushed finish for visible parts Nickel, tin, gold, silver plating via partners |

| Inspection |

Visual check for burrs Gauge check on OD and threads Fit test in plastic when required |

| Packaging |

Tray pack for precision threads Bag + label for standard orders Master Box + Wooden pallet |

| Lead Time |

Repeat jobs: 15–20 working days New tooling/plating: 20–25 working days |

| Drawings Accepted | PDF and STEP file |

Recent OEM Brass Inserts Production

Brass Straight-Knurled Press-In Insert

Brass straight-knurled insert manufactured for press-in installation in plastic housings and injection-molded components.

Thread Standard: ISO metric (M4)

Brass Diamond-Knurled Press-In Insert

Brass diamond-knurled insert designed for press-in installation in injection-molded plastic components.

Thread Standard: ISO metric (M3)

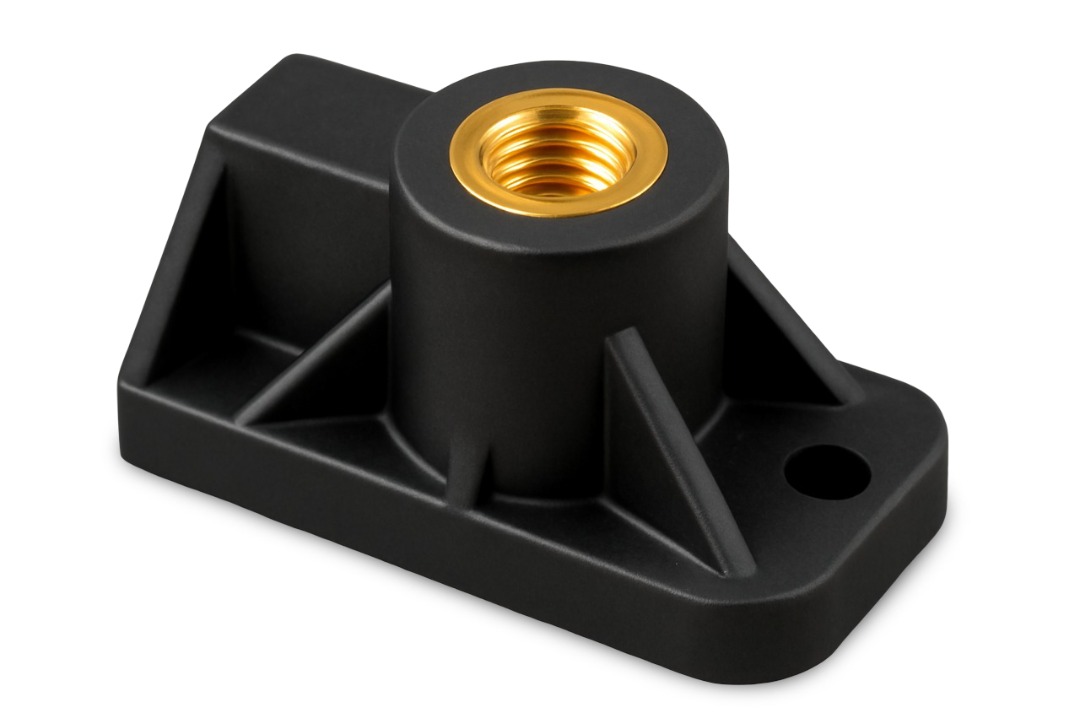

Brass Heat-Set Insert with Diamond Knurled Body

Diamond-knurled brass insert intended for heat-set installation in injection-molded and 3D-printed plastic components for electronics and industrial applications.

Thread Standard: ISO metric (M6)

Brass Diamond-Knurled Press-In Insert with Chamfered

Brass diamond-knurled insert with chamfered thread entry, designed for press-in installation in injection-molded and 3D-printed plastic parts.

Thread Standard: ISO metric (M6)

Brass Heat-Set Insert with Angled Knurling

Angled-knurled brass threaded insert intended for heat-set installation in injection-molded plastic components.

Thread Standard: UNC 6-32

Brass Threaded Insert with Straight Knurling

Brass insert featuring an internal ISO metric M6 thread and straight knurled body for installation in plastic components.

.

Thread Standard: ISO Metric (M6)

Why Use Brass Inserts?

Insert is not just shiny threaded part. It is the perfect balance of strength, corrosion resistance, and thermal conductivity. In plastic molding application, it flow better and does not deform under pressure but soft might be. Brass threads stay clean and resist galling. they do not strip the moment someone grabs screwdriver too hard.

Brass Inserts make assemblies stronger and cleaner. Instead of just forcing screws into plastic, you get repeatable torque and reusability. No cracks and stress marks. Just a solid, finished feel.

Brass Inserts for Plastic Injection Molding

Brass inserts are widely used in plastic molding. They create strong and repeatable metal threads inside plastic parts. Direct screws often strip plastic bosses over time, so inserts are preferred.

Press-in brass inserts work best in rigid plastics. Rigid plastics accept interference fit better. They allow fast assembly in high-volume production. But they need tight outer diameter control and consistent knurling to avoid spin-out. When sized correctly, press-in inserts give reliable pull-out resistance.

Heat-set brass inserts are installed into a pre-molded hole using a heated tool. The heat softens the plastic around the insert. Soft plastic flows into the knurl pattern. When it cools, it hardens and locks the insert in place. This method is used when stronger and more consistent retention is required. It also gives better alignment control than press-fit.

Mold-in brass inserts are placed inside the mold before injection. Molten plastic flows around the insert during molding. As the plastic cools, it forms a mechanical lock with the knurl. No extra installation step is needed. Manufacturers use this for structural housings and heavy-load threaded features.

Brass inserts work reliably in common engineering plastics such as ABS, Nylon, Polycarbonate (PC), and heat-resistant plastics like PEEK. Performance still depends on boss design, wall thickness, and installation method.

Brass is commonly preferred over aluminum for plastic inserts because it resists corrosion and machines easily. Stainless steel is usually chosen only when higher temperature and strength is required.

For detailed thread sizing, classes, and tolerance control, see our brass threaded insert page.

Types of Brass Inserts (Quick Guide)

- Press-in brass inserts - best for rigid plastics, fast assembly.

- Heat-set brass inserts - best for nylon, ABS, PC, PEEK, highest retention control.

- Ultrasonic brass inserts - best for thin walls and automation.

- Mold-in brass inserts - best for maximum pull-out resistance, no secondary install.

- Threaded brass inserts - used when repeat torque and serviceability matter.

Materials - What We Machine Daily

We do not run custom brass alloy. We stock and machine known grades, tight batch control.

- C360 - Best for sharp threads, dry machining

- CZ121 - For fine knurling, good chip control

- C385 - Great for molded-in inserts, smoother tool feed

Each grade cuts differently. We have to adjust speed, chip break, and tooling based on grade. In our one batch of PO-145 needed a new knurling insert at mid-batch due to edge wear. cleaned the groove, ran the rest smooth.

Brass Inserts Manufacturer Capabilities

We manufacture most brass inserts on dedicated automatic brass insert machines, not general CNC lathes. CNC turning is used only for large inserts requiring special features and tighter tolerances.

Production is based on repeatable, dedicated setups for each part number. All inserts are made strictly as per customer drawings for plastic molding and assembly use.

Machining Scope

Standard brass inserts are produced on special-purpose automatic brass insert machines. This SPM machine designed for high repeatability and stable thread quality.

CNC turning is used only when required for:

- Big inserts

- Complex geometry

- Special tolerances

- Non-standard profiles

Blind threads and short thread lengths are produced with controlled threading methods suited to brass inserts. Thread depth and profile are maintained consistently across batches.

Production threads are cut using tools selected for stable pitch and long tool life.

Threads are not forced with soft taps or uncontrolled methods.

Knurls are formed by controlled rolling, treated as a functional feature for plastic retention, not decoration.

Dimensional Control

Outside diameter is typically controlled around ±0.05 to ±0.10 mm depending on insert size and application, and checked on every batch. Knurl height is set to suit your plastic boss.

Roundness is normally controlled around 0.05 mm on critical diameters where required.

Internal thread pitch is verified using Go/No-Go gauges at regular intervals during production.

Process Discipline

Each insert design uses dedicated tooling for that part number, whether run on automatic insert machines or CNC. Tooling and setups are logged and tracked for repeat orders.

Setup records include spindle speed, tool offsets, and fixtures for consistency. The same collets, clamps, and tooling configuration are used for repeat production.

Cutting and threading tools are monitored for wear and replaced before they can affect quality.

Surface Finish and Post-Process

Tumbled finish is the default to remove sharp edges and chips. Brushed finish is used when the insert exterior remains visible in the final product.

Nickel, tin, gold, and silver plating is done through certified partners. After plating, all inserts receive full inspection to detect thread buildup and fit issues.

Quality Checks You Actually Get

Every batch receives visual inspection for burrs and chip smears. Critical ODs and internal threads are checked with gauges.

Where required, inserts are fit-tested in sample plastic blocks.

Packaging and Logistics

High-precision threaded inserts are packed in trays to protect threads. Standard orders are packed in bags with clear labeling, master box and wooden pallet.

Lead Time

Repeat jobs normally ship in 15 to 20 working days. New tooling, special plating, and design changes can extend lead time to 20 to 25 working days.

Small batches are usually sent by air freight. Large volumes are shipped by sea to reduce cost.

Actual lead time can vary based on raw material availability and plating schedules.

Threads - Internal, External, Cleaned Before Ship

- Metric: M2 to M16

- UNC/UNF: 4-40, 6-32, 10-32, 1/4-20

- BSP, NPT available on request

- Through-threaded, blind, closed bottom

- Side-tapped inserts supported

- Tap cleaned, chamfered, light deburr pass on every batch

Maintaining tight thread tolerances requires high-end equipment. While we specialize in inserts, our facility is fully equipped for complex CNC Parts that require multi-axis turning. Many clients ask us about pricing for high-precision work; we actually published a guide on why CNC machining custom parts can be expensive to help engineers optimize their designs for lower production costs.

Tolerances - What We Actually Hold

We do not write ±0.10 mm and hope. We measure. We track. We scrap if needed.

- OD tolerance: ±0.05–0.10 mm typical

- Thread pitch: Go/No-Go checked every 10 to 15 pcs

- Knurl height: Controlled within ±0.10 mm on press-fit specs

- Roundness: Within 0.05 mm on most diameters

Our factory use micrometers, bore gauge and optical comparators for quality checks. No tolerance is “close enough.” We once had to re-run 5000 inserts when a collet slipped and gave us +0.04 mm on OD. Fixed it, logged it, ran it again. Clean.

Surface Finish & Processing

- Tumbled Finish: Default, clean edge removal

- Brushed Finish: On visible external inserts

- Machined Finish: No post-process, raw from tool

- Nickel Plating, Tin Plating, Gold/Silver: Via certified partners

- Heat Treat & Cleaning: Brass does not need hardening, but we degrease every batch before ship

- Packing: Tray pack, bagged with labels, or foam-boxed for critical threads

Application Industries We Supply Brass Inserts To

- Injection Mold Builders (USA, Europe)

- Electronics & PCB Assemblers (Germany, South Korea)

- Automotive Plastic Components (UK, India)

- Medical Equipment Makers (USA, EU)

- Consumer Goods (Global)

Recent jobs:

- 440000 Piece for LED panel maker in Denver, USA.

- M6 threaded heat-fit sockets for an Ohio molding house

- 10,000 press-fit inserts for a plastic medical clip run in Belgium

Types of Brass Inserts and Installation Methods

We manufacture brass inserts for all major install types such as press-fit, heat set, ultrasonic and mold-in. Each needs a different outside diameter geometry, knurling and tolerance. If insert will wrong match? We will insert spins, cracks part and pull out. We cut them right so your installation process will run soooth.

Press-In Brass Inserts

- OD Design: Straight wall and slightly tapered

- Knurl Type: Diamond and straight for perfect grip

- Material Fit: Works best for ABS, Nylon, soft PC

- Use Case: Mounting bosses, standoffs, threaded holes in rigid plastic housings

- Risk: Over pressing can crack thin walled parts

Our press-in inserts are widely used for mounting bosses and PCB standoffs. For assemblies that require height clearance without the weight of brass, we also manufacture precision Aluminum Spacers that match our insert tolerances for a perfect fit in your housing

Heat-Set Brass Inserts

In these method insert dropped into a pre-molded plastic hole and then pushed in using a heated tool. Plastic softens, flows around the knurl, and re-hardens to lock the insert.

- OD Design: Tapered entry, vented or open-ended

- Knurl Type: Helical or diamond

- Plastic Types: Nylon, ABS, PC, PEEK heat tolerant plastics

- Tooling: Hot-tip soldering iron, thermal press, CNC controlled heater

- Critical Detail: OD taper must match hole ID to avoid float and sink

We machine thousands of heat-set brass inserts monthly. For one batch used in PEEK enclosures in the UK, we ran a 5° entry taper and included a chamfer ring. Held ±0.02 mm on OD for clean install across 8 cavities.

Ultrasonic Brass Inserts

Installation using vibration and pressure. Ultrasonic horn vibrates at high frequency, creating heat from friction between insert and plastic then softens plastic and lets the insert sink in.

- OD Design: Shorter length, precise diameter

- Knurl Type: Spiral or multi-start diamond for grip

- Application: Fast install for mass production

- Risk: Too sharp a knurl, wrong horn can overheat and cause flash marks

- Ideal For: Thin-walled parts, tight spacing, automated assembly

Mold-In Brass Inserts (Pre-Insert and Post-Mold Insert)

Installed during the plastic molding process. Insert is placed into the mold before injection, or post-injected into semi-solid plastic.

- OD Design: Flanged or barbed to resist pull

- Knurl Type: Straight grooves or anchor fins

- Usage: Plastic enclosures, connectors, threaded caps

- Advantages: Zero secondary process, strongest mechanical lock

- Requirement: Mold design must allow accurate insert placement

What Makes Our Inserts Hold Better

- Tool sharpened every 2000 pcs - no drag, no burr

- Knurl depth checked every 50 pcs

- Dry-cut strategy - avoids chip weld on OD

- Fixture torque-tested - We actually press them into test blocks

- Reamed pilot samples - So clients can test fit before main run

- Repeatable batches - Same tools, same feeds, no re-tuning every order

Case Studies: Solving Real-World Brass Insert Challenges

- We once had a batch of 5,0000 pieces with blind M5 threads. First tool chipped after 800. We caught it on the gauge, swapped tools and rechecked depths, and kept thread pitch consistent. This is how it should work.

- One of our clients needed a nickel plated insert with foam separators and we ran full plating, inspected 100%, and tagged each bag with a heat lot.

- We once ran a batch of C360 press-fit inserts with tight knurl height control. A customer in Ohio was cracking ABS housings, and it turned out their press fixture lacked a bottom stop. We sent test fit blocks, adjusted knurl height by 0.05 mm, and solved the problem.

- We once tested 5 insert fits across 3 mold cavity types and adjusted knurl height by 0.03 mm for smooth install.

Brass Insert Buyer FAQ

1. Do you make standard catalog brass inserts or only custom?

We manufacture custom OEM brass inserts only. All parts are made strictly according to buyer drawings and requirements. We do not sell catalog and off-the-shelf inserts. .

2. Can you quote and manufacture inserts without a drawing?

A drawing is normally required to quote and manufacture. If a drawing is not available, you must provide a physical sample part for review.

3. Do you support samples before mass production?

Yes. We support 5 to 10 sample pieces or a small pilot batch before full production. Mass production starts only after sample approval.

4. What minimum quantity do you accept?

We do not accept quantities that do not justify tooling and setup cost. Very small one-time orders are reviewed case by case. We focus on medium, large and repeat OEM quantities.

5. What surface finish is normally provided on brass inserts?

Our default surface treatment is tumbled and nitric for brass. Additional finishes such as nickel, tin, and silver plating are provided through qualified partners as per drawing. Raw, untreated inserts are not supplied.

6. What plastics work best with brass inserts?

Brass inserts work well in ABS, Nylon, Polycarbonate (PC), and PEEK. Retention still depends on boss design, wall thickness, and installation method.

7. Who owns the tooling for custom brass inserts?

All tooling, dies, and fixtures developed for your part are customer-owned. Tooling is never reused for another buyer and is dedicated to your part number only.

8. What files do you need to quote brass inserts?

We prefer STEP (3D) and PDF. A PDF alone can work if it is fully dimensioned and clear. DXF/DWG may be accepted for simple parts, but 3D is preferred for complex designs.

Request a Brass Inserts Quote

To request a brass insert quotation, send your drawing and RFQ details.

Please include:

- Material specification

- Quantity requirement (one-time, repeat, or blanket order)

- Critical dimensions and tolerance requirements

- Required delivery timeline

- Shipping terms (EXW, DAP, or DDP)

After receiving your RFQ, drawings are reviewed and any technical clarification is discussed if required. A quotation is issued with pricing and indicative lead time before production.