Custom Online CNC Machining Services in USA, UK, Europe, and Asia

Looking to find a quick and dependable online CNC service in USA and worldwide. We also supply CNC machined components for customers in France, Italy, Germany, Netherlands covering turned and milled parts for industrial applications. Whether you are looking prototype and mass production run.

our platform ensures precise parts with fast delivery and competitive price.

We handle a wide range of material alloy such as aluminum, steel, brass, copper, and bronze, through services

like machining, turning, milling, drilling, broaching, wire EDM and routing.

Request instant quotes for CNC machining online, upload your CAD designs, and get your parts shipped worldwide.

Our top-notch facilities in both the USA and other countries focus on delivering quality CNC machining services

in USA and across global markets.

Why Choose Us for Custom Online CNC Machining Services in USA, UK, Europe

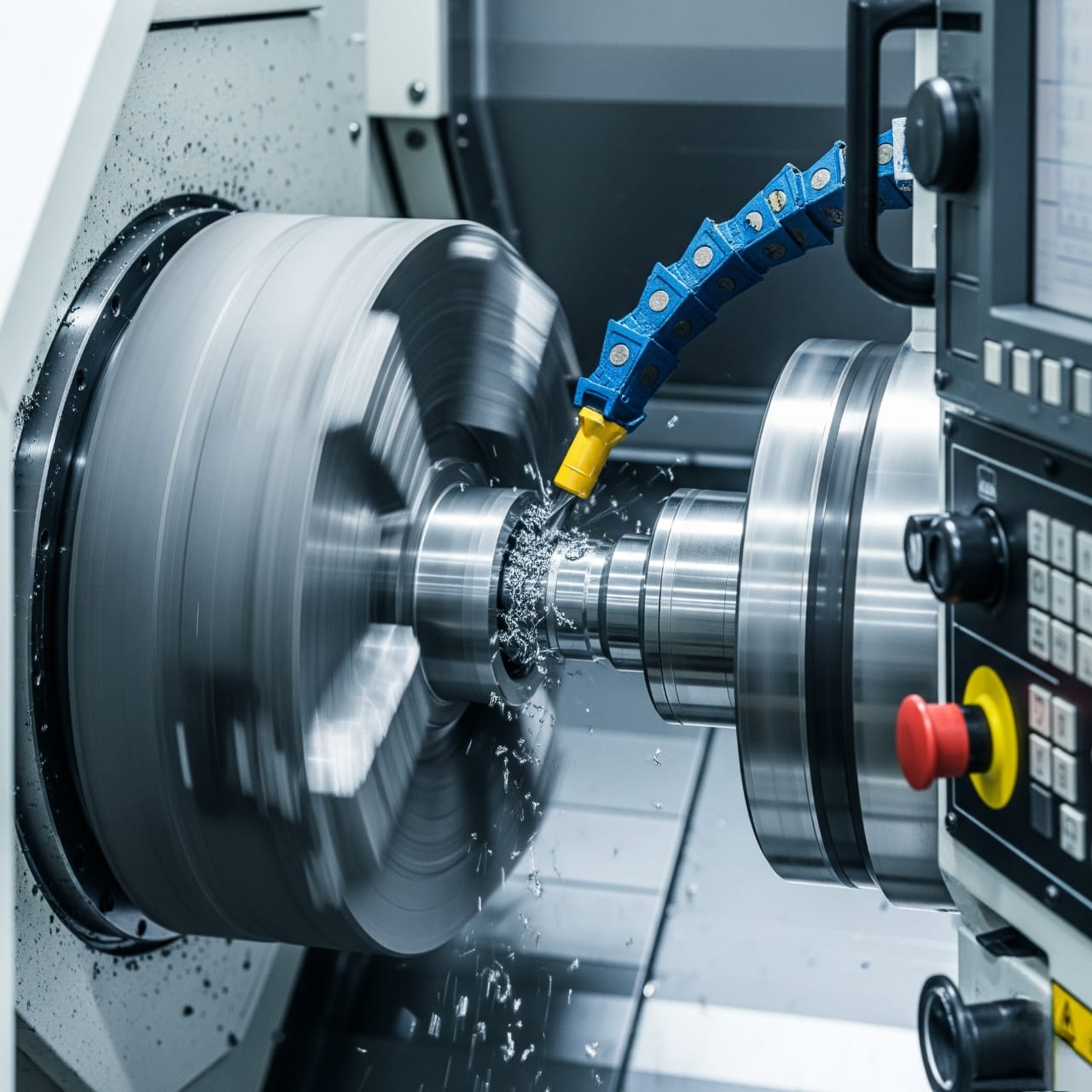

We offer custom online CNC machining services trusted across the USA, UK, and Europe. supported by cutting edge manufacturing

technology, skilled operators, and strict quality controls. Our facilities have multi axis CNC milling and turning center capable

of handling small to large parts with complex shapes and features.

Our ordering process makes sourcing online CNC parts simple and efficient.

We guarantee material tracking, reliable lead times and expert quality control all supported by responsive customer support.

Clients Advantages :

✔ Customizable production size: Make anything from one prototype to large batches of eparts.

✔ Instant support option: Get advice on materials, finishes, and tolerances from etechnical xperts.

✔ Worldwide shipping: Quick delivery covering North America, Europe, and Asia regions.

✔ Certified quality: Receive parts built under ISO standards with inspection reports eavailable on request.

What is CNC Machining?

CNC (Computer Numerical Control) machining uses programmed software to guide machines and tools during manufacturing.

It creates physical parts from 2D and 3D CAD drawings by cutting material removed from a solid piece also called a workpiece.

CNC machining offers more consistent and repeatable results compared to manual machining even with

complicated designs and when producing mass production. This automated process has become

essential across industries due to its reliability, speed, and cost savings.

.

How CNC Machining Works

CNC machining start with CAD (computer Aided Design) file which defines shape of the part. CAD file is converted into G-code. G-code controls movement, speed, tool path, and feed rate within the machine.

Key Components of CNC Machining:

• Controller: Execute the program and send instructions to motor and actuator.

• Machine table: Hold the part in place during machining.

• Cutting tools: These include tools like drills, lathe and end mills that can be swapped as required.

• Axes: Machines have 3 to 5 axes enabling work on complex features and angles

After setting up and calibrating the machine, it follows the programmed instructions with little need for human involvement.

This approach ensures precise results and consistent repetition.

Main Processes of CNC Machining: Machining, Turning, Milling, and Routing

CNC machining uses different methods designed to meet specific requirements:

Key components in the CNC system include:

• Turning: material is rotated, and the cutting tool moves in straight lines. Turning is ideal for creating round parts like shaft, threaded rod, and bushing.

• Milling: A cutting tool spins and shapes stationary part of material. CNC milling machines work on 3,4 and 5 axes. It will help to create complex shapes and vertical features.

• Routing: The routing process works by milling but is suited to shape softer materials such as plastics, composites, and wood. High-speed spindles remove excess material while forming accurate designs.

• Machining: Machining covers all processes that remove material with controlled tools. It includes methods like drilling, tapping, and boring.

Metal CNC Machining Materials

We work with many types of metals depending on your project requirements and how it will perform:

Key components in the CNC system include:

• Aluminum: Grade 6061, 7075, 6063 etc Lightweight, corrosion resistant with anodized, and easy to machine. Ideal for aerospace, automotive, and electronics parts.

• Stainless Steel: Grade SS303, SS304, SS316, SS302, SS202 etc high strength, heat resistance,and corrosion protection. Common use in medical parts, food-grade, and marine components.

• Brass: Grade 316, IS360 , C33500 etc Easy to machine, low friction, and electrical conductivity. Used in plumbing, electronics, and decorative parts.

• Copper: Grade C101, C120, C122 etc High electrical and thermal conductivity. Common in heat sinks and electrical contacts.

• Titanium: Grade 1,2,3,4 etc Lightweight, resists corrosion, and works well with the human body. Mostly used in aircraft and medical implants.

• Carbon Steel: Grade EN8, EN9 etc Strong and affordable for building structures and making machine parts.

Tolerances for CNC Machining

CNC tolerances set the limit on how much a dimension can vary from its intended size.

Smaller tolerances result in greater accuracy but make the process more expensive

Standard tolerance ranges:

• General parts: ±0.005 inches (±0.127 mm)

• Precision components: ±0.001 inches (±0.025 mm).

• Critical aerospace/medical parts:±0.0002 inches (±0.010 mm).

Several factors like the complexity of the design how materials behave during machining,

and the number of movements the machine's axes make affect tolerances. Calibration tools,

temperature controls, and accurate fixturing help maintain consistent results..

CNC Machining Finishes

The look, strength, and function of machined parts all rely on surface finishes. We provide several choices to meet different needs:

• Anodizing: Boosts aluminum's resistance to rust while allowing you to add color.

• Polishing: Create smooth, mirror like surface ideal for low friction application.

• Powder Coating: Forms a tough colored layer designed to handle outdoor use or tough conditions.

• Electroplating: Add metal coating such as nickel and chrome to increase durability and conductivity..

• Passivation: Cleans stainless steel by getting rid of impurities and creates protection against rust.

• Chemical Etching: Makes it possible to create lasting marks on parts and add fine textures to surfaces.

The choice of finish depends on how it needs to perform, meet industry rules, and handle exposure to environmental conditions.

Advantages and Challenges of CNC Machining

Advantages of CNC Machining

• Precision: Manufacture parts with tight tolerances and very little difference between them

• Repeatability: CNC machines, after setup, create thousands of matching pieces without variation.

• Scalability: Fulfill all needs prototype, a small run and mass production.

• Material Flexibility: Handles hard metals, plastics, and even composite materials .

• Efficiency: High speed automation reduces production time.

• Integration: Syncs with CAD/CAM tools to move from design to production.

• Reduced Waste: Tools use efficient paths and layouts to use up less material.

Challenges of CNC Machining

CNC machining comes with some challenges:

• Initial Costs: Buying machines, tools, and software needs a big upfront investment..

• Skill Requirements: skilled technicians can handle programming and setup.

• Design Constraints: It cannot machine certain internal shapes and sharp corners.

• Material Waste: It removes material, which creates leftover chips and scraps.

• Tool Wear: Working with tough materials or precise tolerances can wear tools out faster.

CNC Machining Applications

CNC machining supports many industries such as:

• Aerospace: Engine housing, turbine blade, and bracket.

• Automotive: Custom bracket, transmission parts, and housing.

• Medical: Orthopedic implants, dental fixtures, and surgical tool.

• Electronics: Enclosures, heat sinks, and electrical connector.

• Defense: Military hardware, firearm parts, and sensors.

• Industrial Equipment: Machine parts robotic arms, and custom tools.

It also plays a big role in research and development. It allows teams to create quick iterations and stick to designs when driving innovation.

FAQ-CNC Machining

How much does CNC machining cost?

Cost depends on material, part complexity, finish type, and quantity. Aluminum parts with basic designs might only cost a few dollar, but titanium parts can cost much more. We recommend requesting a custom quote.

What is the maximum part size for CNC machining?

Our machines handle parts as big as 60" x 30" x 25", but it depends on the setup. Bigger parts might work if specialized tools are used.

How does CNC machining differ from traditional machining?

Manual work is needed in traditional machining. CNC machining uses automated instructions from computers. This method brings higher precision faster production, and the ability to work on complex designs. It also helps lessen operator tiredness and avoids many human mistakes.

What are your inspection options for CNC machining?

We provide both basic and detailed inspections including following methods:

✔ First Article Inspection (FAI).

✔ Coordinate Measuring Machine (CMM) reports.

✔ Verifying surface finish and flatness.

✔ Certifying material and hardness.

Will I need to pay tariffs on internationally produced parts?

Tariff rules depend on the country. We handle both domestic and international orders. Our experts can guide you on the best shipping options to reduce costs and avoid delays.

Get a Free CNC Quote Online Today

Send us your product drawing now to receive a quick quote with no strings attached.

If you need CNC mass production high grade parts, we provide efficient, expert machining solutions across the globe.