If you are an OEM Buyer and sourcing CNC machined parts in bulk quantities, then aluminum is probably on your RFQ list. It is one of the easiest metals to cut, lightweight, and cheap, but that does not mean it is simple. Sometimes it's very complex if the setup is wrong.

We have experience in aluminum CNC machining for over a decade for our OEM clients. The job ranges from small batches to mass production.

Where Does Aluminum Come From?

Aluminum starts out as bauxite ore. It is processed into alumina through refining, then smelted into pure aluminum ingots. Most of the aluminum we machine is not pure but is an alloy of aluminum. That is, other metals such as magnesium, zinc, and copper are also added to the aluminum. This gives the aluminum strength, corrosion resistance, and machinability.

In our shipments to our customers, we mostly include material certificates. It will help the buyer to better idea of composition. That is because many industrial OEM buyers do not just buy 'CNC aluminum parts' but they buy parts in specific alloys that have raceable chemical properties.

What Types of Aluminum Are Used in CNC Machining?

Not every aluminum grade behaves the same in a CNC lathe and mill. Some cut like butter. Many other sticky like gum.

Cast aluminium

Good for nearly perfect shape. But structure can be inconsistent.

Wrought aluminium

Reliable and stronger. Ideal for precision parts.

Heat-treated aluminum

Increased hardness for load-bearing components

When our one customer from USA sent us a large housing order in 7075-T6, the stock arrived straight, but the first roughing pass showed chatter marks. We swapped out the insert geometry, slowed the RPM slightly, and the chatter disappeared. That is the kind of small adjustment that makes or breaks a job.

Benefits of Using Aluminium for CNC Machined Parts

Weight to strength ratio

Aluminum has good strength and lightweight capability. You can have a bracket that weighs half of what a steel part does. Without giving up the stiffness you need for most assemblies. That is the reason why so many products now shift from other metals to aluminum.

Corrosion resistance

With or without anodizing, aluminum can last for years in outdoor environments. We supply aluminum neutral bars to an electronics company USA for installations. Not a single one came back corroded.

Machinability

It's easy to cut and helps a lot in the tool life. We can hold tight tolerances in mass production, especially in grades like 6061. It means faster cycle time and lower cost.

Surface finish quality

You can achieve the best quality finishing in aluminum. Bead blasting and anodizing take it to the next level.

Popular Aluminum Alloys for CNC Machining

6061-T6

Smooth machining, stable under high-speed milling, and good for anodizing as well. We can hold ±0.01 mm tolerances without effort. Most of our export shipments in 6061 are housings, neutral bars, and brackets for automation equipment.

7075-T6

Stronger and harder than grade 6061, but strength comes with slightly more tool wear. Commonly used in aerospace and defense. When cutting deep pockets, we keep an eye on chatter - swapping to sharper carbide inserts helps.

2024-T3

More copper content percent means it can corrode if left bare, so anodizing and coating are recommended.

5083

Excellent corrosion resistance best for marine environments. It is a softer alloy, so it can smear if the tool edge is not sharp. We slow the feed slightly and use high positive rake inserts.

MIC-6 Cast Aluminum

Stable, flat, and great for milling flat surfaces without distortion. This is a cast and stress-relieved plate mostly used for tooling and jigs.

We always match the alloy to the application. Not just check availability. A drone part in 7075 grade might be overkill, and a heavy-duty shaft in 6061 might fail in service.

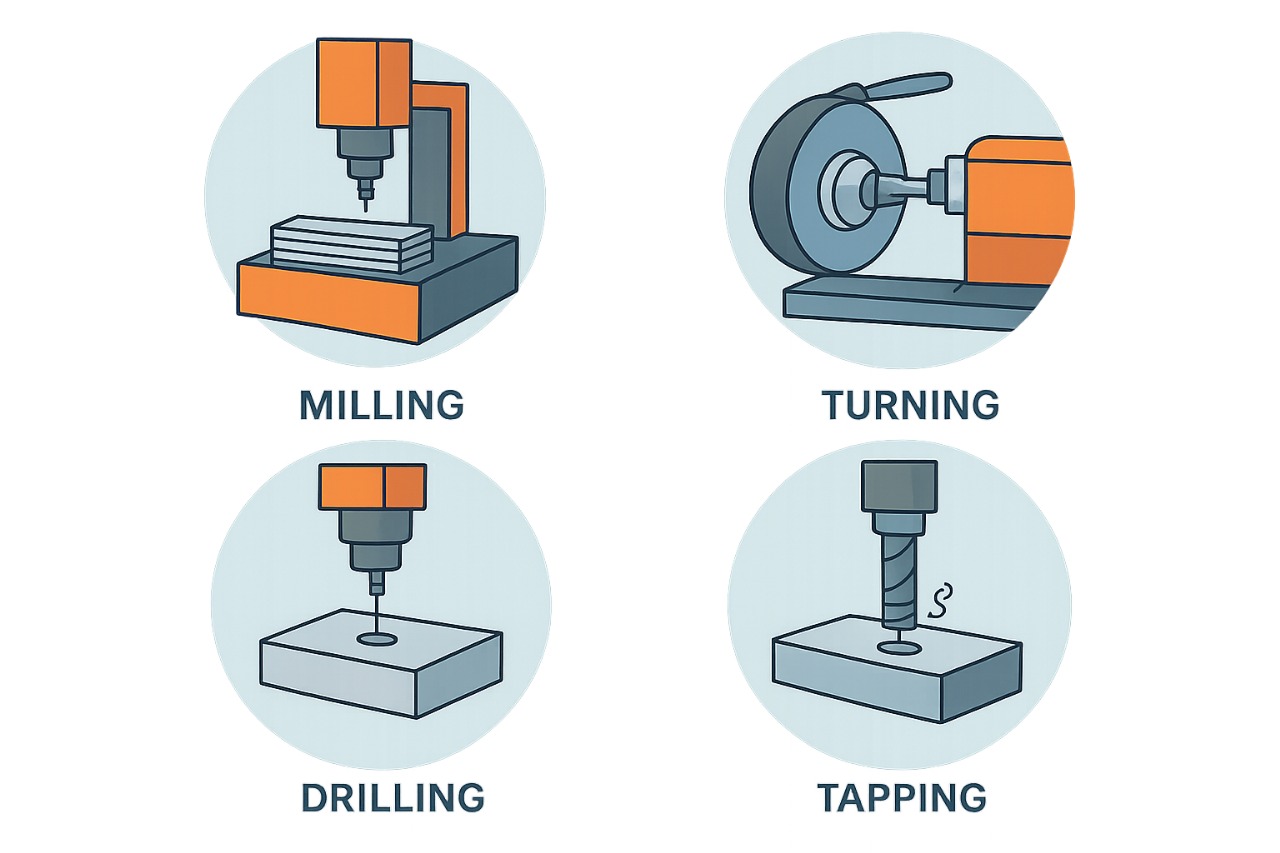

What Are the Most Common Aluminum CNC Machining Processes?

When people hear Aluminum CNC machining part, they usually think of milling or turning only. The reality is that most production runs mix of processed. Even if the parts start on a turning, it might end up on a mill for flats, slots, and holes.

Turning

For anything that rotates along a central axis, bushings, spacers, threaded shafts - we run aluminum bar through CNC lathes. With aluminum, chips come off light and stringy, so chip breakers on the inserts are a must.

Milling

This is where blocky parts and brackets take shape. High spindle speeds and aggressive feeds keep the cycle times down.

Drilling & Boring

Aluminum drills beautifully, but oversized holes are easy to make if the feed is too slow. For tight-tolerance bores, we rough drill, then finish bore to size.

Tapping & Thread Milling

Fine threads in aluminum cut clean, but the risk is over-torquing and pulling the threads out. For softer alloy grade, we prefer milling thread for better control.

Pocketing

To remove weight inside a part without touching the outer walls.

Profiling

To get smooth edges and surfaces, often as the final last step.

The choice of process is not about what looks easiest. It is about what holds tolerance over the full batch, whether that batch is 100 pieces or 50,000.

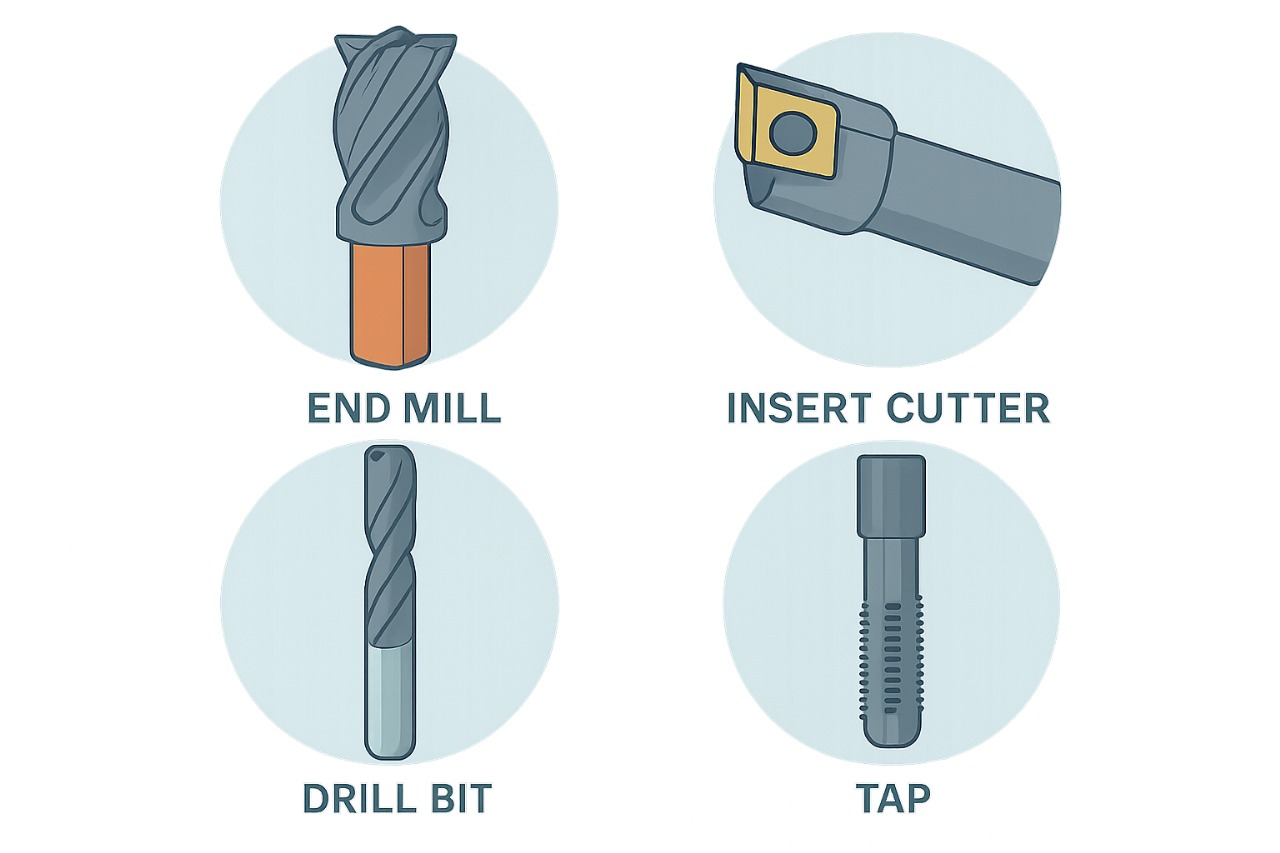

Tools for Aluminium Machining

Aluminum is easier than stainless, but the wrong tooling setup will still ruin a batch.

Cutting Tools

For turning, we like sharp, high-positive rake carbide inserts. For milling, coated end mills work well because aluminum does not stick to them as much. TIAIN looks fancy, but it traps heat, and with aluminum you want the heat to go out with the chip, not into the tool.

Tool Geometry

Sharp edges matter more than people think. A dull edge will smear the surface, and once that happens, polishing will not save it.

Coolant

Coolant depends on the job. Most of the time we flood it to keep everything cool. But if the part is going straight to anodizing, we go with air blast so there is no staining.

Speeds and Feeds

Aluminum can handle high RPM and fast feeds, but not always. In deep 7075 pockets, too much speed will make it chatter.

Chip Control

Chip control is another headache. Long stringy chips will wrap around the tool and leave scratches. On big 7075 runs, we sometimes swap to wiper inserts so the chips break short and the finish comes out right in one pass.

Tool selection is where machining experience shows. The insert geometry, coating, and condition directly control part quality.

Get CNC Aluminum Parts

If you need custom OEM cnc aluminum parts, brackets, bushings,

spacers, housings, and adapters in the USA or Europe and built by real operators, then these are your companies.

Request a Free CNC Aluminum Parts Quote now.