Neutral Ground Bar looks very simple, milling holes, threads, and a flat bar, but they do heavy work inside an electrical panel. They keep circuits balanced, carry return current, and help prevent faults. A wrong choice of neutral bar can mean overheating, wasted energy, and even safety risks too.

Electricians, buyers, and sellers often face the same debate. Which is best, the Copper neutral bar or the Brass neutral bar? Both are reliable, used worldwide, but the question is whether they perform the same way. My simple answer is no. Copper gives you raw conductivity. Brass gives you strength and cost benefits. Now, the challenge is knowing which fits your job best.

In this guide, we walk through every angle, from electrical performance to cost and installation. By the end, you will know exactly which is best, where copper makes sense, and where brass holds the edge.

Understanding Neutral Bar Functions in Electrical Systems

Ever notice that row of white wires in a panel? They are all landing on one thing, the neutral bar. It doesn’t look like much, but it’s essential. It gives electricity a way to return to the source safely. Without it, The system loses balance fast.

Think of it like a round-trip ticket. Hot wires send power out, the neutral bar brings it back. That back-and-forth keeps your lights on, appliances stable, and circuits happy.

In many setups, the neutral is also bonded to ground. For Safety. If something goes wrong, a short fault ,that connection lets the breaker trip instead of sending current through your toaster or, worse.

From small breaker boxes in homes to control panels in factories, the role doesn’t change. It’s a simple bar. But without it, nothing works.

What is a Neutral Ground Bar and Its Role

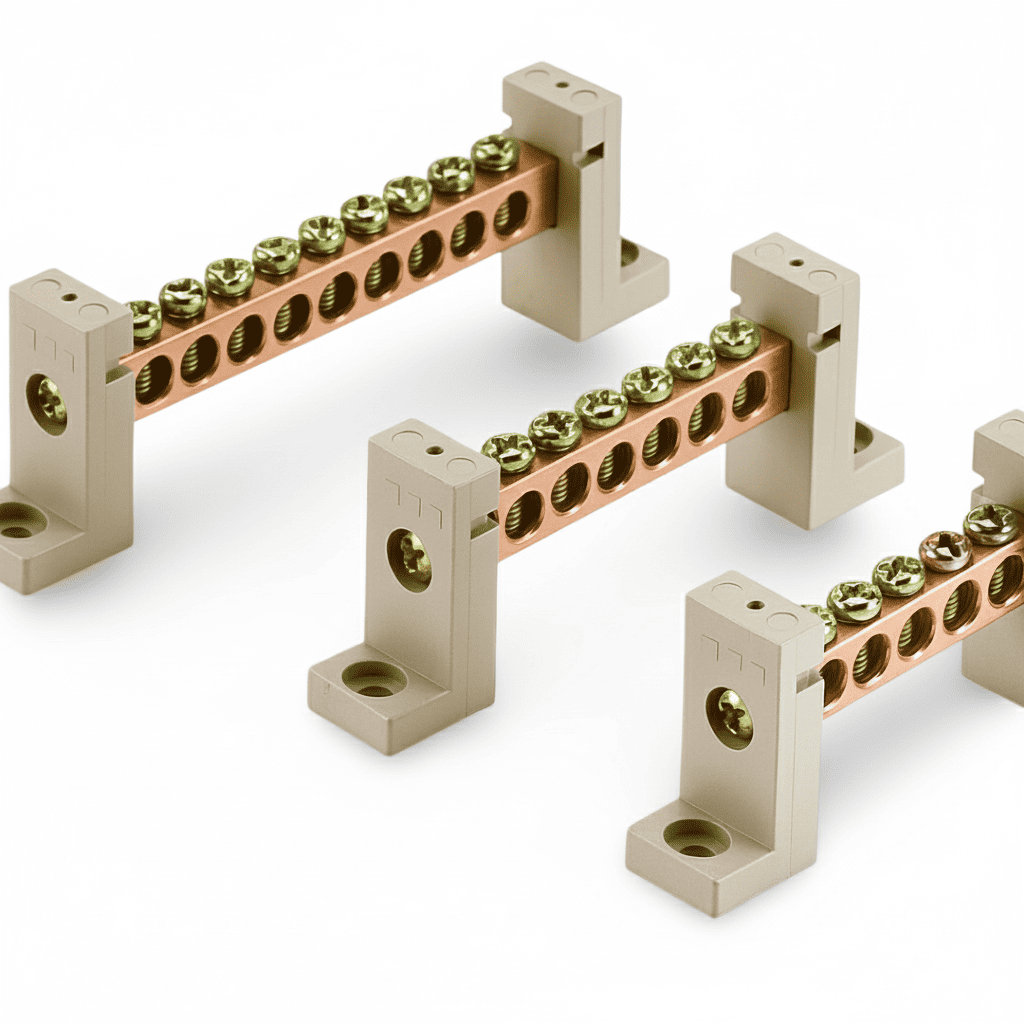

A neutral ground bar is a strip of metal (copper, brass and aluminum) bar with screw terminals, a very simple geometry. Electricians mount it inside a panel to hold multiple neutral and ground wires in one place.

Its job is to give each wire a safe connection point. Without it, wires would pile up, twist together. And result is, create a mess that can lead to faults.

In small home panels, the neutral and ground often share the same bar. In big industrial panels, they use separate bars. Both keep the wiring clear and safe.

We take an example for better understanding. In our workshop, we have many machines, each circuit sends its neutral wire back to the bar. Instead of loose wires hanging everywhere, they line up in one row. This makes it easier to trace a fault if something trips.

Copper Neutral Bar: Properties and Performance

Ok, let’s start with the copper neutral bar first. Copper is the first choice in many control panels. The reason is very clear. It carries current with very little resistance. Also, copper gives you high conductivity. It means less heat, more energy saving, and safety as well.

Copper also resists wear. You can tighten and loosen screws many times without issue. Electricians know this very well. A copper bar can take repeated torque without the threads stripping too easily.

It also handles harsh environments better than any other metal. In damp basements and coastal areas, copper fights corrosion longer than most metals.

Ok, think about a small apartment block. Each floor draws heavy power for heaters, stoves, and air conditioners. copper neutral bar ensures the load is shared safely, without overheating. That reliability is why you see copper in many modern panels, from homes to factories.

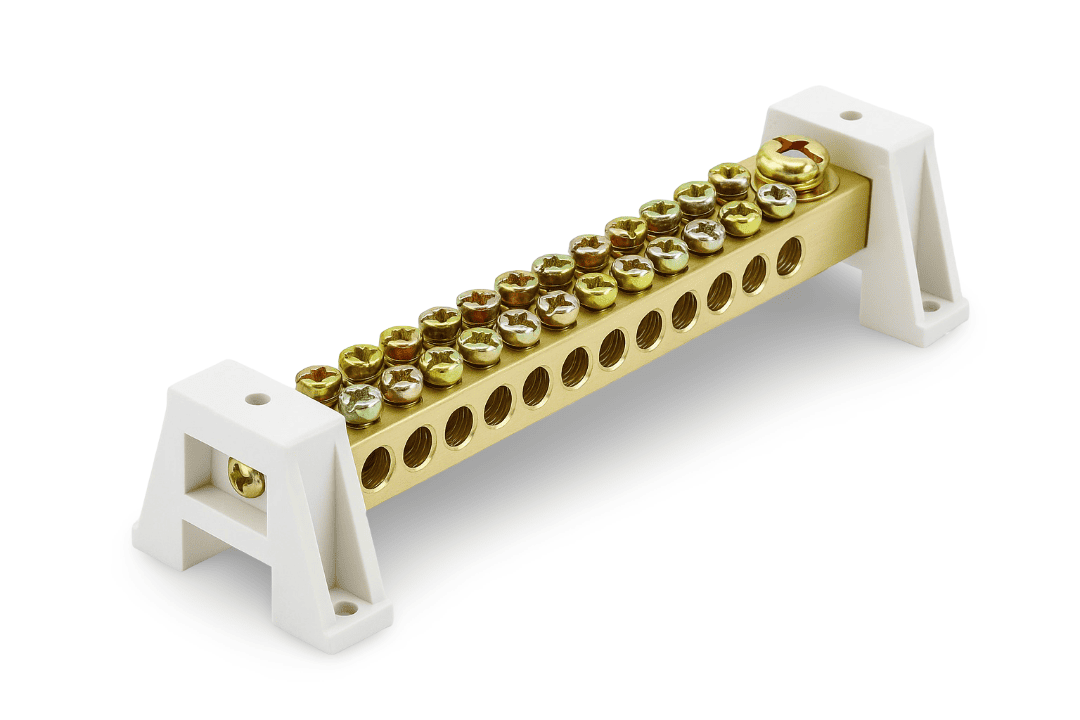

Brass Neutral Bar: Characteristics and Applications

Brass is not good conductive as copper, but it has its own advantages and strengths. It is strong, easy to machine, and holds threads well. It is a good choice when you have too many screws that will be tightened and loosened over time.

Brass also costs less than copper, which is a bigger advantage nowadays. Every buyer needs cheaper product. For panels where no need for extremely high current levels, this balance of price and strength.

You often see brass neutral bars in smaller distribution boards, control panels, and older residential systems. They do the job safely when the load is moderate.

Small shops are good example we can take here. In small shops, only lights, fans, and a few machines, a brass neutral bar is enough. No need for a copper bar here. It keeps wires organized, is durable, and saves cost compared to copper.

Head-to-Head Comparison: Copper vs Brass Neutral Bars

| Feature | Copper Neutral Bar | Brass Neutral Bar |

|---|---|---|

| Conductivity | Very high (about 97% IACS) | Lower (about 28% IACS) |

| Heat Handling | Stays cooler under heavy load | Heats faster with high current |

| Strength | Softer metal, threads can wear | Stronger, threads last longer |

| Corrosion Resistance | Very good, but may tarnish | Good, holds up well in dry conditions |

| Cost | Higher | Lower |

| Best Use | Heavy power systems, high current | Light to medium loads, cost-driven panels |

Simple takeaways:

- Copper is best for carrying current. If you run large, heavy loads, it is the best choice for you.

- Brass is cheaper and holds screws better. For project budget is matter brass makes sense.

- Copper is like high-capacity water pipe. It flows more without heating. Brass is more like a sturdy smaller pipe. It works best if demand is not too high.

Conductivity and Electrical Performance Analysis

Copper carries current much better than brass. Its conductivity is about 97 percent IACS. Brass is closer to 25-30 percent. That means a brass bar resists current three to four times more.

At 100 amps, a copper bar may lose 10 watts as heat. A brass bar of the same size can lose 35 watts. More heat means higher temperature and faster wear.

At 50–60 Hz, skin effect is not an issue. Current spreads through the full bar.

The real weak point is often the screw joint. A loose screw adding 0.01 ohm at 100 amps makes 100 watts of heat. That is why proper torque and clean contacts are critical.

In faults, copper stays cooler and keeps voltage drop lower. Brass lasts longer at the threads but heats faster.

Both need protection in damp areas. Without plating or coating, oxides raise resistance over time.

Very simple rule, copper for high loads and efficiency, brass for lighter duty and lower cost.

Cost Analysis and Selection Guidelines for Neutral Bars

| Feature | Copper Neutral Bar | Brass Neutral Bar |

|---|---|---|

| Initial Cost | High upfront cost, but reliable | Lower upfront cost, more budget-friendly |

| Electrical Conductivity | Excellent, low resistance, minimal energy loss | Moderate, slightly higher resistance |

| Corrosion Resistance | Very high, lasts longer in humid & outdoor environments | Moderate, may need inspections in corrosive conditions |

| Maintenance | Minimal, rarely needs replacement | Periodic checks recommended |

| Fabrication & Machining | Requires careful handling, hard to shape | Easier to machine, cut, & bend |

| Suitable Applications | High-current circuits, industrial or critical systems | Moderate-load systems, budget-conscious projects |

| Lifecycle Cost | Lower over time due to reliability | Can be higher if replacement and maintenance is needed |

| Practical Tip | Worth the investment for long-term reliability | Choose only if load and environment allow |

Selection Guidelines From Experience

High Current Systems: For high current system, choose copper. It will prevents energy loss and overheating

Budget-Limited Projects: Brass works best conditions are controlled and load moderate.

Outdoor and Corrosive Environments: Brass degrade faster if exposed. Copper is best for corrosion resists.

Custom Machining Needs: Brass is easy to cut, bend, and drill. Copper is tough for shapes.

Practical Tips

Don’t make a decision on material price alone. Consider the total lifecycle cost. Copper is safer than brass. For mixed-material setups, you can combine copper and brass and make compatible connectors. But before checking electrical compatibility, it is important to avoid hot spots and galvanic corrosion.

Installation and Maintenance Considerations

Installation Tips

Installing a neutral bar is not just placing it in the control panel. You have check surface, it must be flat and firm. Loose connections cause heat, sparks, and failure. Copper bars bend easily, so handle carefully.

Brass is easier to shape, but do not over-tighten. Always use torque tools and too much force can damage the metal. Always check alignment with your eyes and hands. Small misalignment can cause problem later.

Maintenance Tips

Inspect Often: You have to check regularly for discoloration, loose screws and corrosion.

Clean Gently: Use a soft brush and mild cleaner on copper.. For outdoor and moisture conditions, brass needs more care.

Watch Temperature: High-load systems can develop hot spots.

Replace When Needed: Copper lasts many years. But for brass may need replacement sooner in very harsh conditions.

Practical Advice

Do not skip proper installation to save time and money. A poorly installed bar will fail quickly, even if the material is good. Keep spare terminals and note torque settings. Follow an inspection schedule for safety and reliability.

Final Words

Choosing the right neutral bar is about more than price. Consider load, environment, and maintenance. Copper gives long-term reliability. Brass works for moderate systems and tight budgets. Make decisions based on real conditions, not just cost.

Get a Free Brass neutral bar & Copper Neutral Bar Quote.