If you have ever pressed your brake pedal and felt it sink a little too far, you know that uneasy feeling. I have seen it many times in the shop. The pads look fine, the rotors check out, but the real issue hides in the brake line union, that small fitting that holds everything sealed under pressure.

When a union starts to corrode and loosen, it does not scream for attention. It leaks quietly. A drop here, a soft pedal there, until one day the brakes feel spongy, and you know something is wrong.

That is why I always tell drivers: never underestimate small parts. A bad union can compromise the whole system. Once you understand what to look for, catching the problem early is easy - and it can save you from a complete brake failure.

What is a Brake Line Union?

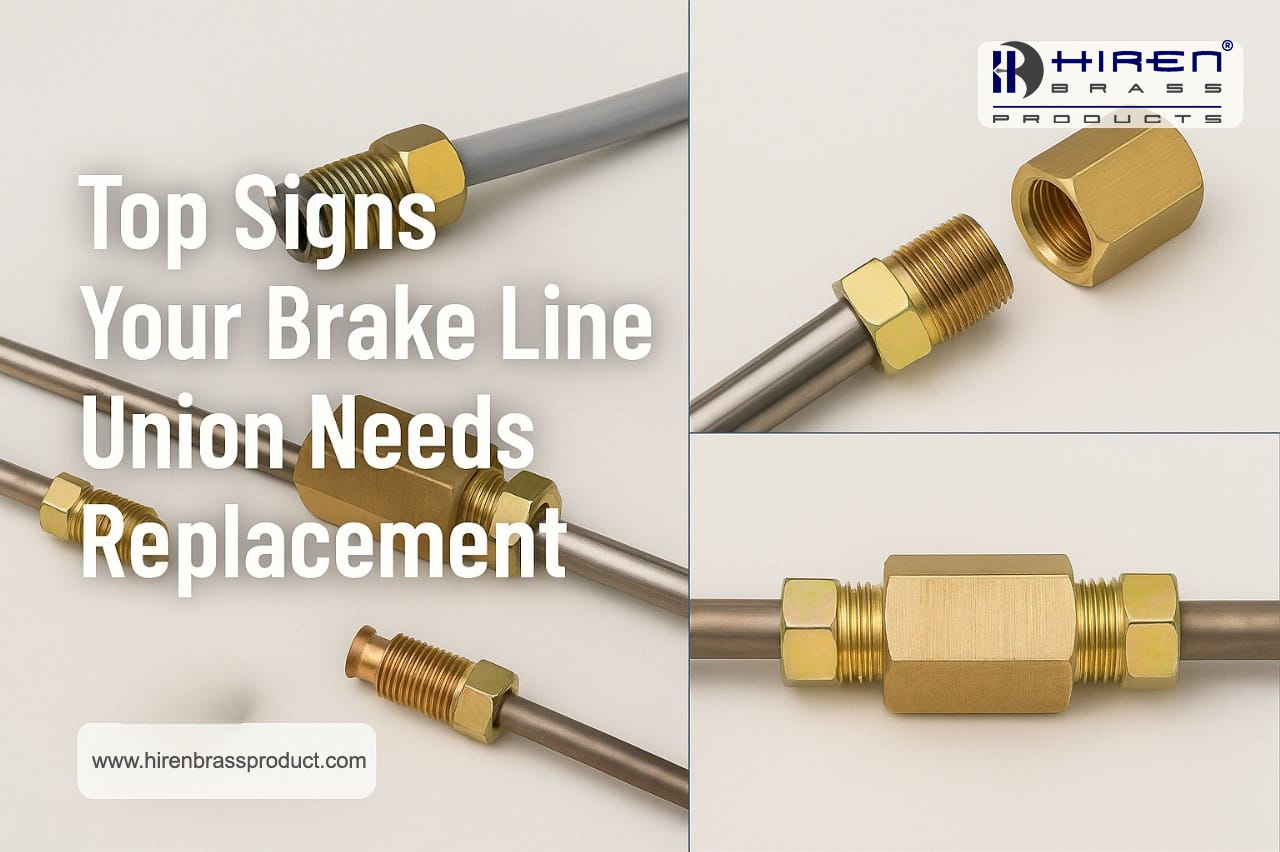

If you have ever replaced a section of brake line fittings, you have seen the small connector that joins two metal tubes together –yes, that is the brake line union. It looks simple, but it does a heavy job. It keeps hydraulic pressure sealed tight while fluid moves from the master cylinder to the calipers.

A proper union is built to handle extreme pressure, heat, and vibration. It has to seal metal-to-metal, no leaks allowed. When that seal goes, the whole system pays for it. That is why understanding what this small part does - and how it fails - matters more than most people realize.

Role and Importance in Brake System

The brake line union is the link that keeps your hydraulic system sealed and balanced. It connects different sections of brake tubing so fluid pressure moves evenly to every wheel. Without it, the system would leak the moment you press the pedal.

When I inspect a braking setup, I always check the unions first. A small crack can bleed off pressure before it ever reaches the calipers. That is why a soft pedal often points back to this tiny fitting.

In short, the union’s job is simple but critical - hold pressure, stop leaks, and keep the system stable under stress. If that seal fails, even the best pads will not save braking performance.

Common Types of Brake Line Unions

There are a few types of brake line unions you will see in most vehicles. Each one fits a specific job and pressure range.

Flare unions are the most common. They connect hard brake lines made from steel or brass. The ends are flared to create a tight metal seal when tightened.

Compression unions are used in temporary repairs. They seal with a sleeve instead of a flare. They work, but not for high-pressure systems. I never recommend them for long-term use.

Banjo fittings connect brake hoses to calipers .They use a bolt and copper washers to seal fluid inside. You will find them mostly in disc brake setups.

Each type must match the system pressure and line material. A wrong fitting and poor flare can cause leaks, which means weak braking and higher risk.

Key Signs You Need Brake Line Replacement

Brake lines do not fail overnight. They give warning signs long before they stop working. You just need to know what to look for.

The first thing I notice during inspections is fluid around the fittings. Even a small wet mark means the seal is no longer holding pressure. That leak might start slow, but it never stays that way.

Corrosion is another clear signal. Rust on the lines the walls from the inside out. Once it starts to flake, replacement is the only fix.

Pay attention to how the pedal feels. If it starts feeling soft or takes longer to stop, fluid loss is likely. Ignoring it can lead to complete brake failure.

When these signs appear, replacing the line and union is not optional. It is the only way to keep your braking system safe and predictable.

Leaks, Corrosion, and Visible Damage

Leaks are the easiest sign to spot. If you see wet spots near a brake line and around a union, fluid is escaping. Once it starts leaking, pressure drops and braking power goes with it. I have seen small leaks turn into full failures within days.

Corrosion works slower but does more harm. Rust eats the outer wall first, then creeps inside the line. When that happens, the metal gets thin and brittle. One hard brake, and the line can burst.

Visible damage is another warning. Look for cracks, bends, and crushed sections. Even a small dent can restrict fluid flow. If you spot any of these signs, replace the line before it puts you in danger.

Brake Warning Light and Pedal Feel

The brake warning light is your first signal that pressure is not right. When that light stays on, the system has detected a drop in fluid or pressure. Do not ignore it.

Pedal feel tells the same story. A soft pedal means air is trapped in the line. A sinking pedal means fluid is leaking somewhere. A hard pedal usually points to blocked lines.

When the warning light appears and the pedal starts changing, stop and inspect the lines immediately. These signs always show up before total failure.

Brake Line Inspection Tips

Checking your brake lines does not need special tools, just patience and good light. Start by looking along the entire length of each line. Focus on joints, bends, and unions. Those areas fail first.

Wipe away dirt and moisture. Fresh fluid will show as a shiny patch. That means a leak has already started.

Run your fingers along the line. If you feel roughness, rust is eating the metal. Replace it before it cracks under pressure.

Check the mounting clips and brackets. Loose fittings let the line vibrate, which causes wear marks and weak spots.

Finish by pressing the brake pedal while someone watches underneath. Any movement, swelling, around the union means the line is not sealing properly. Replace it before the next drive.

Brake Line Replacement Cost Overview

Brake line repair costs depend on how much of the system is damaged. A single union cheap to fix. Full replacements take more time and labor.

On average, small repairs cost less than a full set of lines. When corrosion spreads through the system, the entire line set usually needs replacement. That adds labor hours and more brake fluid for bleeding.

Shops charge based on vehicle type and line material. Steel costs less, but copper-nickel lines resist rust and last longer. Spending a bit more now prevents the same problem later.

In most cases, proper parts and clean installation save money over time. Replacing the line once is cheaper than repairing leaks again and again.

Keep Your Braking System Reliable - Choose Quality Unions

The safety of any brake system depends on strong, leak-free connections. A weak union can fail under pressure, no matter how good the rest of the setup is. That is why using precision-made unions matters.

We supply durable brake line unions built for long service life and consistent sealing. Each piece is machined to exact tolerance and tested for hydraulic performance.

If you manufacture or repair braking systems, choose components that last. Request Quote today for high-quality brake line unions designed for safe, stable performance.