You do not feel CNC machining through a screen. You hear it. The spindle winds up, then cuts in. The smell of coolant hits your nose. Sharp, bitter. Chips fly fast. If the tool is good, the cut is clean. If the fixture is off by even a hair, the part shifts, and you are starting over. This is not some perfect lab process. This is a factory floor.

CNC stands for Computer Numerical Control. In plain talk, it means a machine moves based on code. That code tells the tool where to go, how deep to cut, and when to pull back. It does not get tired. It does not forget a move. The machine repeats the same job, part after part, hour after hour.

In our factory in the India, most jobs start the same way. A buyer sends a drawing. Sometimes it is a good file. Other times, we open it and find dimensions missing, threads unlabeled, or no tolerances at all. That is fine. We call the buyer. Ask questions. Fill in the blanks. Once we know what they need, we get to work.

First, we pull the stock material. Brass. Bronze, Copper, Aluminum. Stainless. Sometimes PEEK or nylon if it is a non-metal job. We cut it to size. Mount it tight in the vise or chuck. Zero the machine. Then the fun begins.

Every CNC Parts manufacturer machine runs on G-code. That code is made by a CAM program. We feed in the drawing, set toolpaths, pick the right cutter, and post the file. Once that file is in the controller, we load tools, check clearance, and press cycle start. The machine moves fast, but you watch close. First part is always a test.

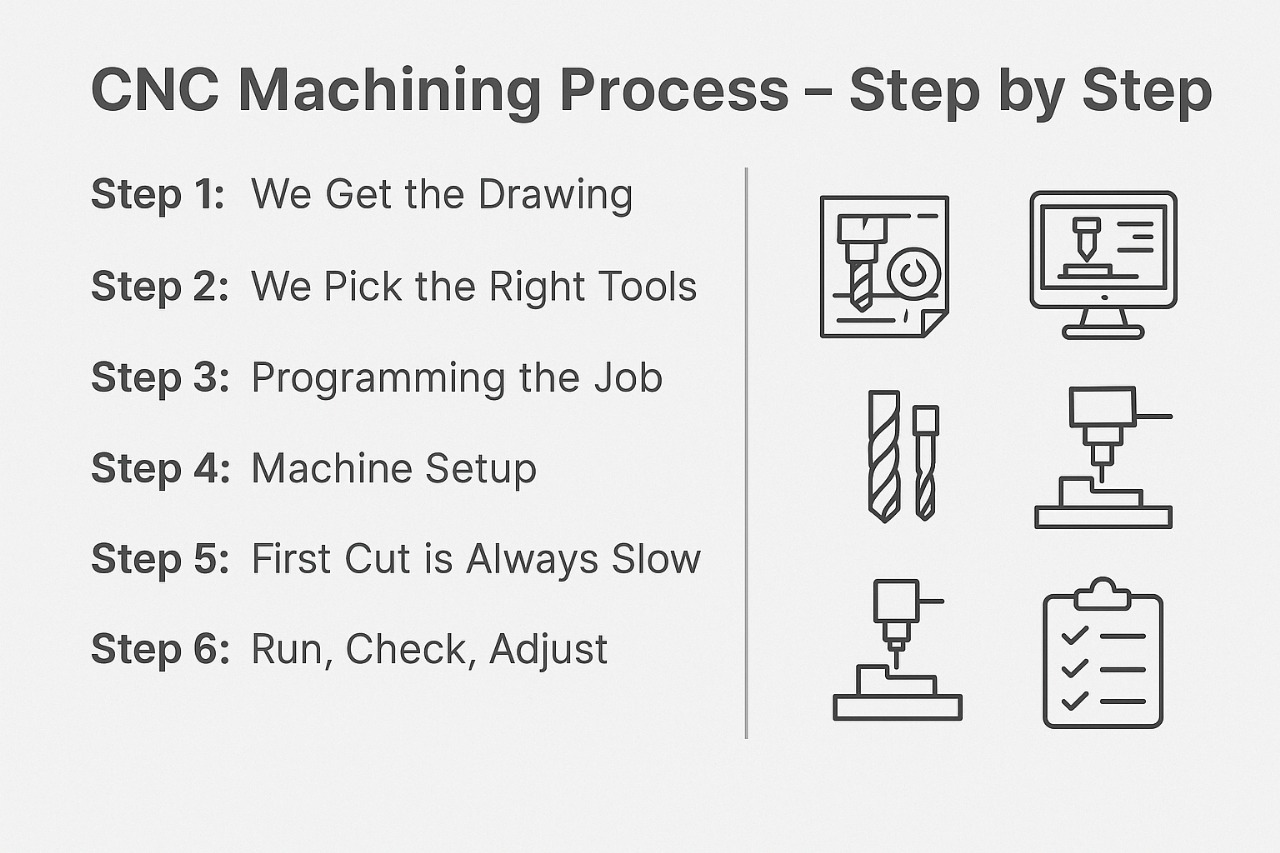

CNC Machining Process – Step by Step

This is how our factory operates, and it's probably how the majority of factories in the United States handle CNC machining. It's not a brochure procedure. It is sharp, loud, clear, and never perfect the first time.

Step 1: We Get the Drawing

The customer typically sends a STEP file, or just a pdf sometime. which is how we obtain the product drawing. In any case, we open it and examine the diameter details like pocket depths, corner radii, and thread callouts. We don't proceed if something doesn't feel right. We confirm over the phone with the buyer and work together to fix it.

Step 2: We Pick the Right Tools

We select the appropriate tool, carbide cutter is not necessary for everything. good 2-flute tool works well for brass and aluminum. Slower speeds are necessary for stainless. Before we even consider programming, we match the tool to the task.

Step 3: Programming the Job

After dropping the drawing into CAM, we gradually construct the cut. clearance initially. Next are the pockets. Holes endure. Lead-ins and ramps reduce cutter chatter. We search for crash points, clamp clearance, and tool deflection zones. This isn't a guess. Planning is involved.

Step 4: Machine Setup

The raw stock is clamped. It might be fastened to a fixture plate, in soft jaws, or in a vice. Regardless, we use a height setter to confirm Z zero, check for rock, and tap it down. Everything will be thrown off if there is just one chip beneath the part. We check it twice. so we can reduce errors

Step 5: First Cut is Always Slow

Not any factory achieve speed in new product without error. We run without coolant. First, let the tool hover. After that, we turn on the coolant and run it slowly. We complete the cycle if it cuts smoothly. If not, we stop and correct it. Don't guess in the middle of a run.

Step 6: Run, Check, Adjust

We continue to check every part in a few cycles after the first successful part. depth, bore sizes, and threads. A single sample cannot be trusted. When tools wear, we modify offsets. Every change is recorded.

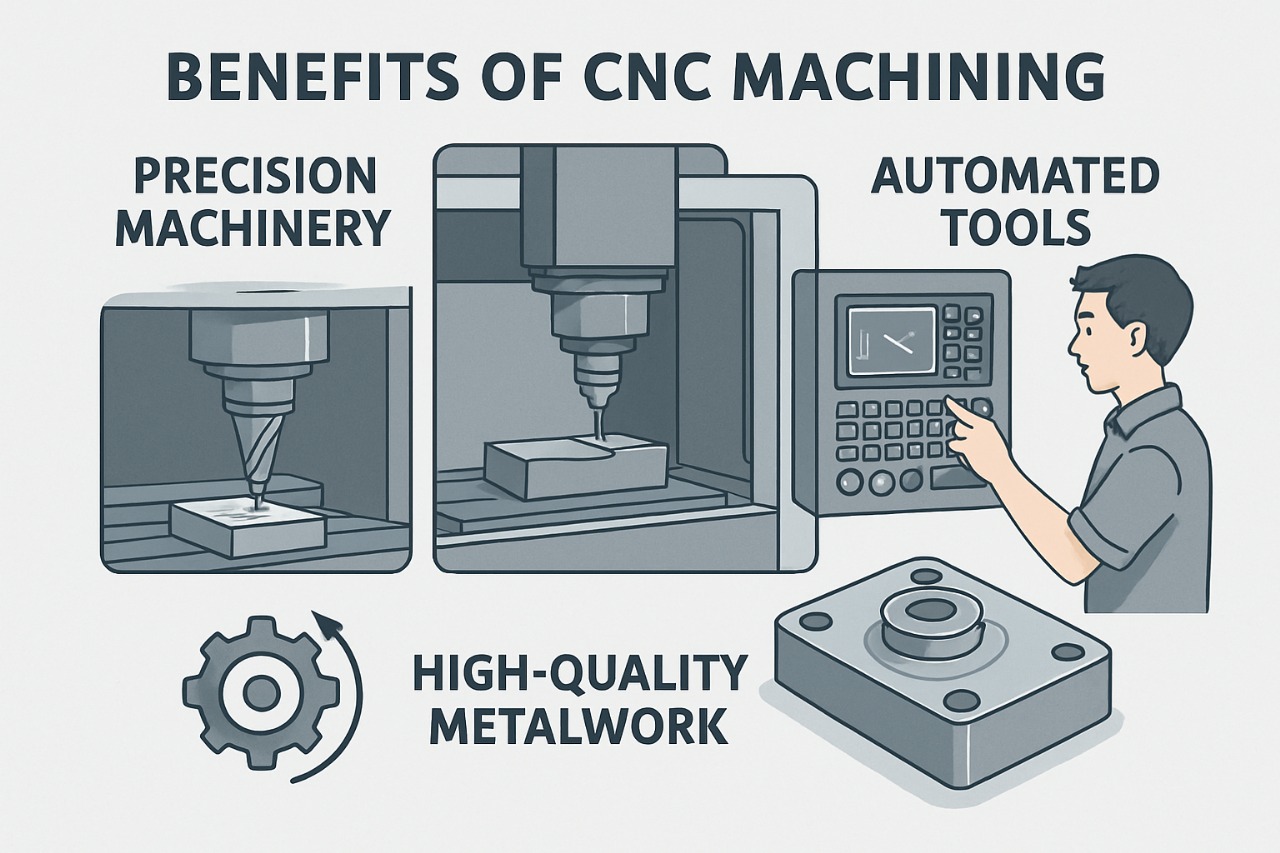

CNC Machining Benefits

I have make parts on manual machine as well, like old school but now 3-axis and 5-axis advance machines available. Here is what makes CNC worth it on real floor not just in specification sheet.

- Accurate and predictable results: CNC doesn't care if you're exhausted or if this is your third shift of the week as long as the setup is sound. It strikes the path. identical cut. The same pass. It repeats like clockwork as long as the program is clean. That implies less rework and fewer second checks.

- Fewer Mistakes = Less Waste: We used to spend half a day setting up manual machines. Now that the first part has been proven, the others follow set-up. fewer parts rejection. Reduce the overflow of the scrap bin. Additional parts have been packed.

- One Operator, Many Machines: I have witnessed a single man simultaneously operate three milling machines. After loading part A and initiating the cycle, he proceeds to part B, checks the threads, and prepares part C. With manual machines, that never worked. Skilled workers can increase output with CNC.

- Tight Work in Hard Material: Bronze, copper, and stainless steel. On a bad day, these eat tooling. However, CNC maintains finish and tolerance with the proper feeds and a low RPM. We have held 500 pieces of 316 stainless steel within ±0.05 mm.

- No Guesswork in Repeats: Pull the file, check the tool list, and run it again if the last batch produced excellent results. You can get the same results each time. It saves hours of setup. Knowing that part #1287 from 2024 will match part #1287 in 2025 is important to customers.

CNC Machined Parts Applications – Real Jobs We Run

Brass Inserts

Brass Inserts are run by the tray full. Molders all over US use it. Tight OD tolerances, solid knurl, and clean threads are required for these parts. A batch was once rejected due to minor burrs. I picked things up quickly, and now each batch is examined by hand before packaging.

Aluminum Control Housings

6061 aluminum grade used mostly for Aluminum CNC Parts . These are installed in sensor blocks, control panels, and enclosures. Face passes come first, followed by pockets and tap holes. While some are anodized, others are left raw. Twice a month, a Chicago customer places an order for the same part. The same print every time. The same fit every time.

Bushings and Couplers in Stainless Steel

Slow, heavy work. These parts frequently require smooth surface finishes and clean internal bores. We frequently replace the inserts, run them wet, and keep an eye on tool wear. We installed 800 stainless bushings for an Ohio pump builder last winter. Just two were reworked.

Plastic Spacers and Brackets

Delrin and nylon move when pressed, but they cut softly. They warp if you clamp them too tightly. They melt if you cut them too quickly. We always keep the table clean and use slow passes and sharp cutters. These wind up in cleanrooms, electrical panels, or food equipment.

Copper Fittings

Sticky but soft. If your cutter is sharp, it works fine. We make a lot of flat rings and press-fit bushings. In a week, a buyer from California required 500 copper parts. With a single tool change in the middle, we completed the double shift.

Real Work Looks Nothing Like the Brochures

Brochures say CNC is clean and perfect. They are wrong. It gets loud. Coolant sprays. Sometimes the chip curls just right. Sometimes it clogs up and you have to pause and clear it out by hand.

One time we ran a batch of brass inserts. Simple OD, thread, knurl. First ten looked great. Then the twelfth one had a crushed thread. Turned out the insert had shifted. The chuck jaws were smooth from wear. We shut it down. Swapped jaws. Reset the code to back off pressure. That fixed it. Most shops would have sent bad parts. We stopped and fixed it before it became a problem.

That is the thing. CNC machines follow orders. They do not check their own work. That is still our job. We check diameter with a micrometer. Depth with a height gauge. Threads with a ring gauge. If a part fails, we figure out why. Wrong offset? Dull tool? Poor fixture? Fix it. Rerun it. Get it right.

And yes, sometimes mistakes cost you. A few years ago, one guy crashed a 3-flute cutter straight into the part. Wrong Z offset. Cutter snapped. Holder bent. Machine alarmed. Job delayed. That was a $600 mistake in ten seconds. But he learned. Now he dry-runs everything. Moves slow first. Speeds up only when safe.

Why Buyers Stick with CNC Precision Machining

People do not come back for fancy language. They come back when their parts fit right the first time. That is what CNC delivers when the job is done right.

You can trust it to repeat. That is the first thing that matters. We once machined a housing that had five bores and three tapped holes per side. The first one took some setup time. By the third, we had it dialed in. Ran two hundred of them. Every one passed inspection. Taps were clean. Flatness held. That job paid for itself in labor savings alone. No touch-up. No scrap.

Another big benefit is material range. Aluminum runs fast and cuts smooth. Brass stays sharp. Stainless cuts slow but strong. Every material has its tricks. We change RPM, feed, coolant, toolpath. CNC lets us fine-tune all of it. One profile might need a climb cut. Another, a straight pass with a chamfer to break the edge. It is not guesswork. It is adjustment. That control is what keeps tolerances tight.

Fixtures help too. You do not get good parts on bad setups. One time we had a run of plastic brackets. The parts kept lifting under the cutter. Turned out the vacuum table had uneven pull. We scrapped six parts before switching to a mechanical hold-down with clamps and a soft backer plate. Problem gone. Same cutter, same code, different fixture. That is how small changes can save whole batches.

Where CNC Parts Go And Why It Matters

We get all types of buyers. Some just want prototypes. Others need full runs. What they all want is the same thing: no surprises.

In the USA, most CNC buyers are serious about tolerance and lead time. Medical buyers want clean threads, tight bores, no burrs. Aerospace asks for traceable material, inspection sheets, and finish certs. Industrial buyers care about cost per part and tool life. We hear the same questions:

- Can it hold ±0.05 mm?

- Can you run 300 per week?

- Can we anodize after machining?

- Will the threads pass ring-gauge check?

Yes, if the setup is right and the operator pays attention. That is where experience beats equipment.

We have machined parts for small shops in Texas, machine builders in Michigan, and molders in the Carolinas. Same machines. Different goals. The guy in Texas wanted stainless guides. The Michigan shop needed aluminum motor plates. The molder needed brass inserts with no flashing and clean knurls.

Each one had their own priorities. We adjusted feeds, swapped tools, changed hold-downs. One job needed back-facing. Another, undercutting with a custom tool. None of it was copy-paste. Every part had to be thought through.

CNC Machining Is Not Push-Button

People think CNC means you just press start and walk away. That is a myth.

We had a job that ran clean for five hours. Part number 48 came out with a burr on one hole. Then 49, same thing. Turned out the cutter had dulled just enough to push material instead of cutting it clean. We paused the job, replaced the tool, touched off again, and reran 48 and 49. They cleaned up fine. But that shows you CNC machines need eyes on them.

We check parts at intervals. Usually first piece, then every tenth. For some parts, every five. Depends on the risk. If it is a customer-fit part, we check more. If it is a low-tolerance spacer, we let it run longer between checks. You learn over time what needs watching.

What Makes a Good CNC Factory?

Not machines. Not fancy photos. Not glossy websites.

What makes a factory good is how it handles trouble. A missed thread. dropped part. jammed tool. customer change mid-run. We have had all of it.

A factory that catches those things, fixes them, and keeps your job on time that is the shop you stick with. That is what we aim to be.

We once had a buyer who sent a wrong file. Missing countersink depth. We caught it before cutting. Called him. He sent a new version. We updated the code and still delivered two days early. He now sends us everything.

Another time, a batch of parts came back from plating with discoloration. Not our fault, but we took it on. We polished the batch again, re-plated locally, and ate the cost. He did not even ask. But he never left after that.

Request a Free CNC Quote

If you are sourcing precision CNC parts and want someone who actually machines them not just sells them then you are in the right place.

We machine parts every day. Steel milling parts, aluminum turning parts, aluminum blocks, stainless pins, plastic fixtures. Tapped. Milled. Turned. Inspected.

You send a drawing, we ask the right questions. We quote real timelines. We use real machines, not empty promises.

Request your Free CNC Quote today.

No guesswork. No missed details. Just parts that work the first time.