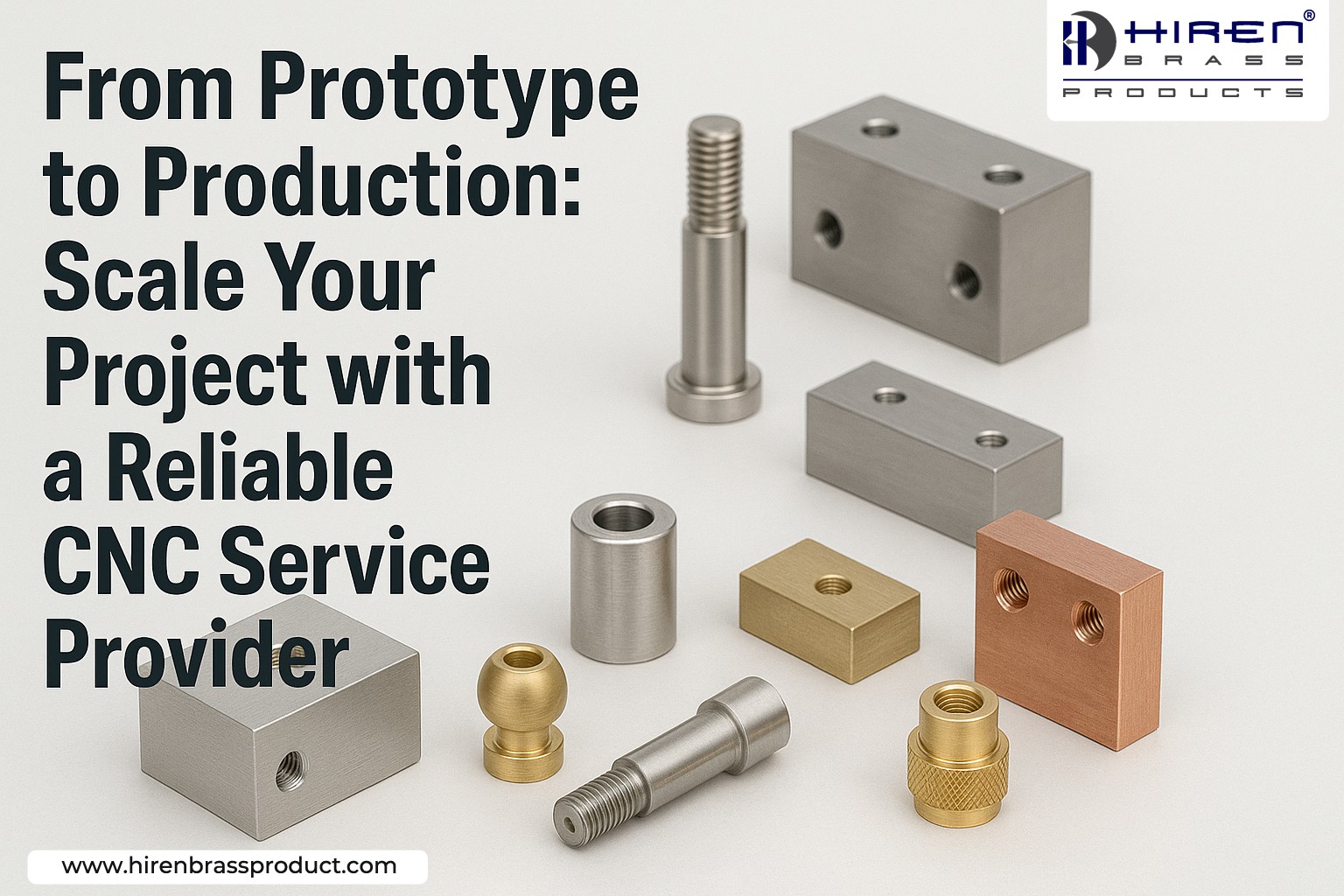

A CNC parts service provider changes how fast a project moves from idea to a working part. Prototype machining needs tight tolerances, stable setups, and real materials like 6061-T6, 304, or POM when the part requires turning, milling, or a combination of both operations.. These parts show the real behavior of a design before you commit to tooling or high-volume manufacturing. Rapid machining also exposes weak geometry, poor fits, and tolerance stacking problems that 3D printing usually hides.

Scaling a project demands more than a machine shop that cuts a single sample. You need a team that understands cycle time, tool life, repeatability, and DFM adjustments that keep the part stable in production. A reliable CNC partner helps you correct issues early so the prototype moves into production without redesign.

A projects move faster when the supplier communicates clearly, understands engineering drawings, and delivers parts that match the model. A strong CNC provider supports this with predictable lead times, certified materials, and controlled machining routines.

This sets the stage for the sections that follow.

CNC Services for Rapid, Iterative Prototyping

Rapid prototyping depends on machining that reacts fast to design changes. CNC machining gives you real material behavior, so you see how aluminum, steel, and plastics respond under actual cutting conditions. That matters because a printed prototype cannot show tool access limits, heat buildup, and fit problems. CNC prototypes let you run tests that match real production behavior.

An iterative project needs parts that match the model every time. A stable CNC setup delivers that repeatability without forcing you into expensive tooling. You can adjust a radius, change a wall thickness. This speeds up design validation and keeps engineering decisions grounded in real tolerances.

Prototyping also exposes weaknesses fast. Thin walls flex. Sharp corners crack. Unsupported bosses fail under machining forces. CNC machining reveals these issues before the design reaches production, which saves time and prevents costly redesign.

Accelerating Design Validation with Precise CNC Machining

Design validation moves faster when the prototype holds real tolerances. CNC machines deliver predictable accuracy, and this accuracy shows how a part fits, aligns, and loads under real conditions. A tight bore, a flat face, or a controlled slot confirms if the model behaves as expected. These checks cannot come from rough samples.

Surface finish also plays a role. A clean finish shows how parts slide, seat, and assemble. Poor finish hides defects during early testing, so precision machining becomes the only way to see true functional behavior. You also catch misalignment, interference, and tolerance stack issues early because the dimensions stay consistent from piece to piece.

A reliable CNC machining service keeps this process predictable. You get short lead times and direct communication, so design iterations move without delays caused by long-distance suppliers.

The Importance of Design for Manufacturability (DFM) Consultation

DFM prevents problems that appear only after machining starts. A machinist sees tool access issues, deep pockets that overload cutters, or sharp corners that break during milling. These problems increase cost and slow production. DFM removes these issues before they reach the shop floor.

Material choice affects manufacturability too. Aluminum cuts differently than 4140 steel. Ignoring these differences creates unstable tolerances and unpredictable surface finishes. Reviewing the design early avoids those problems and keeps the prototype aligned with real production behavior.

Small changes improve performance. A fillet added in the right place reduces tool stress. A corrected chamfer improves assembly. A revised wall thickness strengthens the part during machining. These adjustments make the part easier to produce and more stable when you scale to higher volume.

The Strategic Advantage of a Partnering CNC Service Company (Global & Local)

A strong CNC partner changes how fast a project scales. A shop with real capacity keeps the workflow steady. This stability prevents delays when you move from a few prototypes to steady production.

A partner with global and USA capability gives flexibility. Some parts need tight tolerances and fast communication. USA machining handles that stage with predictable lead times and certified materials. Larger volumes benefit from global operations that run long cycles at lower cost. A balanced supplier uses both without creating gaps in quality.

Engineering support matters. A CNC company with real experience understands how aluminum, steel, stainless, and plastics behave under machining forces. This keeps the part stable across different batch sizes. Many vendors lose control when volume increases because they change setups constantly. A reliable partner avoids that behavior with documented routines.

This mix of global reach and local speed gives you a path from prototype to volume without breaking the process.

Supply Chain Security with Reputable CNC Services in USA

Supply chain stability becomes critical when a project scales. USA CNC services reduce risk because the logistics route stays short. Delays from customs, long transit time, and unclear documentation disappear. This keeps production moving when the timeline gets tight.

USA machining also improves communication. Engineering questions get answered fast because the team works within the same time zone. Drawings get reviewed without misunderstanding. Revisions move into production without long pauses.

Material control stays stronger inside the USA. Certified grades like 6061-T6, 304, 316, 17-4PH, and 4140 come from verified suppliers. Traceability remains intact because the documentation follows strict rules. This prevents confusion about alloy composition or heat treatment status.

A reputable USA CNC provider keeps quality records, tooling logs, and inspection sheets ready for repeat orders. That documentation keeps every batch aligned with the first run. This level of control strengthens the supply chain and protects scaling projects from unpredictable vendors.

Ready to Scale? Contact Your Next CNC Machine Company Partner

Scaling needs a CNC partner that holds accuracy, manages deadlines, and keeps material control stable. A shop that understands prototype behavior and production behavior can move your part through each stage without losing tolerance. This depends on predictable machining, documented routines, and operators who adjust tools before the part drifts.

A reliable CNC company supports aluminum CNC parts, steel parts, brass parts, and plastics without changing quality from batch to batch. The workflows stay consistent because the same inspection plan follows the job from the first sample to the final production run. That stability protects your schedule and prevents redesign.

If you need controlled machining, clear communication, and a supplier that handles prototypes and full production runs with the same discipline, you can shift the work to us without slowing the project.