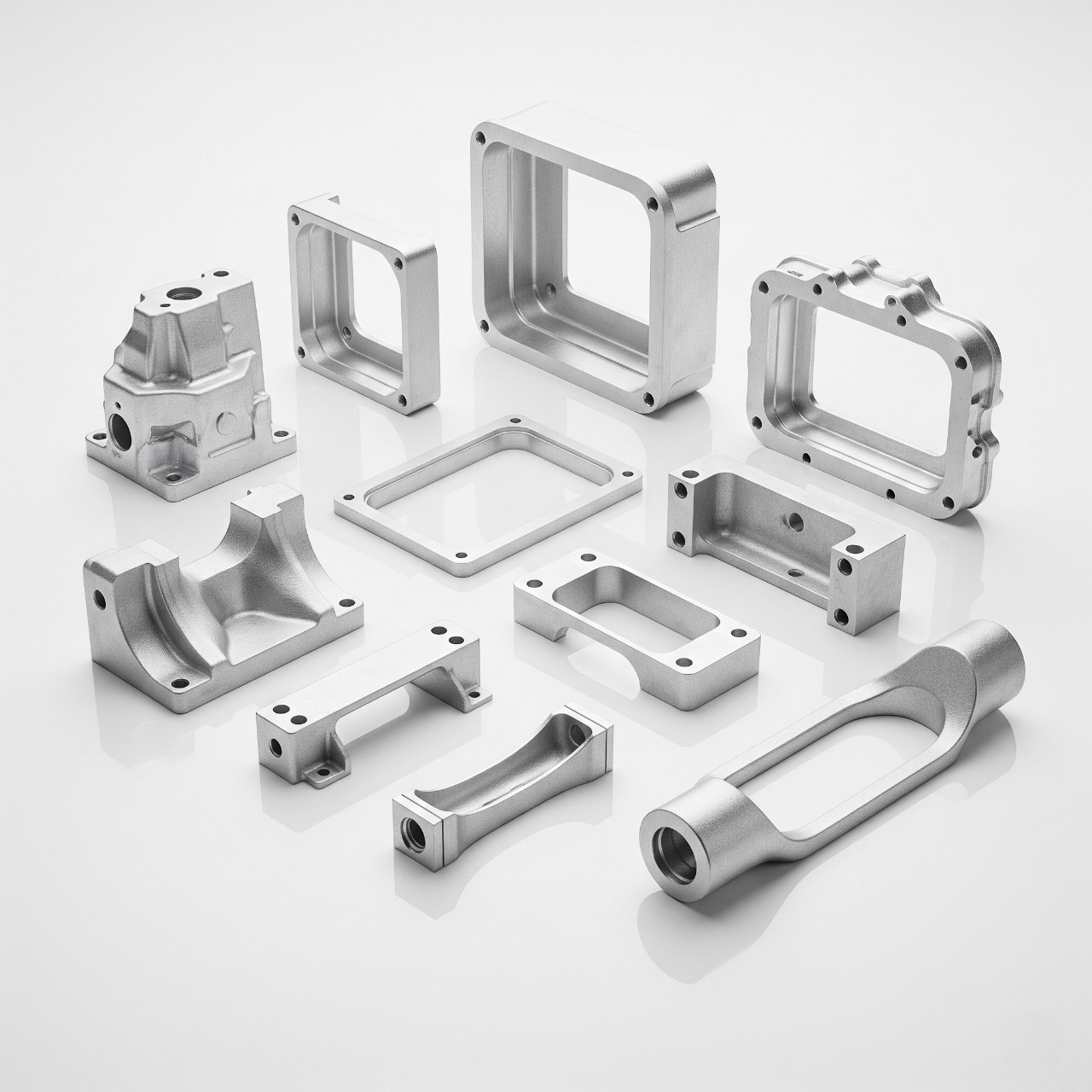

Finding good CNC Parts suppliers is not about who has the flashiest website. It is about who shows up when the machine breaks, when the thread tolerance is tight, when the job calls for 200 aluminum cnc parts in four days. This is not a list pulled from ads. These are shops that machine real parts. We work with buyers in the USA and Europe who need cnc turning parts, enclosures, housings, and custom jobs. Some shops run lights-out. Some run two shifts with a single lead. But they all deliver, and they all know what to do when a tool snaps mid-cycle. That is how you know it is real.

1. Hiren Brass Products

Location: USA, exports to Europe

They run everything from brass inserts to 7075 enclosures. This is not a reseller. It is a working factory. We saw them pull a full tray of aluminum parts off the line when the finish came out cloudy. Rechecked coolant mix. Adjusted speed. Fixed mid-run. They use multi-axis mills, turning centers, and EDM for inserts. Most parts ship within 10 to 15 working days.

Processes: 3-axis, 5-axis, EDM

Materials: Aluminum, brass, stainless, bronze, copper, steel

Tolerance Range: ±0.05 mm

Volume: Over 10000 parts/month

Industries: Defense, electronics, plastics

Certifications: ISO 9001:2015, CE, ROHS

Call to Action: Request a Free CNC Parts Quote

2. Titan Precision CNC

Location: Ohio

Their spindle has been turning since the early 2000s. They are still using the same inspection table. It is worn, but flat. They machine medical grade aluminum housings and fiber optic casings. Once had a burr show up at 400 parts. Found tool wear, updated the offset, and finished the run with zero returns.

Machines: Haas, Doosan, Okuma

Processes: Milling, turning, post-deburring

Clients: Aerospace tiers, optical firms

Note: Tends to over-inspect

3. Alloy Millworks

Location: Texas

They can handle heavy metals SS304, 316, and bronze. They run rough material but clean output. they have case where scale from casting was ruining inserts. They pre-scrubbed blanks in vibratory tank, they did it, ran clean afterward. They handle oilfield couplers, forklift components, flange plates.

Focus: Heavy material work

Finishing: Grinding, heat treat outsource

Good At: Slow jobs with tough specs

4. CorePoint Machining

Location: Michigan

This factory handles small batch aluminum cnc parts. Did a job for a drone builder and ten sets of frames, 5-axis milled. a mis tapped hole halted the first batch. They reprogrammed to spot drill slower and saved the rest. That is a shop that pays attention.

Machines: Brother Speedio, DMG Mori

Specialty: Thin wall parts, small batch

Materials: Aluminum 6061, 7075

Industries: Robotics, consumer hardware

5. DeepCut USA

Location: Pennsylvania

Runs night shift. They built a reputation making brass inserts and turned pins. One of their machinists once caught a jammed chip that was burning parts. They stopped the job, rewrote the path, added a dwell, and the cut cooled. No issues after. Solid team.

Processes: CNC turning, knurling, slotting

Materials: Brass, steel, Delrin

Parts: Inserts, pins, spacers, electrical fittings

6. Alpha Sharp CNC

Location: California

Clean shop. They make control panel housings, heatsinks, and sensor brackets. On one job, a batch came back anodized wrong. They took the hit, reordered raw stock, reran it, shipped again in four days. Their staff knows where jobs fail and how to catch it.

Industries: Electronics, automation, biotech

Certifications: ISO 9001, ITAR ready

Finishes: Bead blast, anodizing, laser mark

Tools: In-house tool library

7. Turner Forge Co.

Location: Illinois

If you need cnc turning parts, these guys run three lathes all day. Nothing fancy. Just consistent. They make bushings, couplers, lock sleeves. Not a word &oval. 800 pieces were produced at one point. The pitch of the thread dropped. Part 27 is where they discovered it. Tool reset. Not a scrap.

Focus: Turned parts only

Materials: Brass, copper, 1144 steel

Volumes: 100 to 10,000 pieces

8. Northfield Machining

Location: New York

They managed a medical testing fixture project. Tapped ends and tight holes. Everything needed to pass the fit test. The edges of one piece were dull. They failed to pack it. The set was pulled. polished. checked again. sent it the following day. Anyone can operate a machine. Not many people give that kind of care.

Machines: Haas, shop-built inspection station

Parts: Spacers, brackets, assemblies

Certs: None listed, but consistent delivery

9. Blueframe Precision

Location: North Carolina

The owner was a toolmaker once. His cuts reflect that. In 7075, they created a special set of guide rails for a packaging machine. Two cameras malfunctioned. He redesigned the ramp angle to fix it. fixed the section using knowledge; no changes were made to the code. It's not common.

Factory Type: Owner-run, hands-on

Services: CNC milling, prototyping

Parts: Low-volume builds, tooling blocks

10. IronHill Engineering

Location: Indiana

Their DFM review skills are strong. They call before cutting if a file is entered incorrectly. One job that had a customer mark the thread depth incorrectly was saved. IronHill saw it, fixed it, and continued to run it. They have a stable process. With proper documentation and inspection sheets, jobs are sent out.

DFM: Included with quoting

Certs: ISO pending, in-house QA

Jobs: Medical brackets, sensor enclosures

What to Expect When Working With These Factories

None of these companies are perfect. That's not the objective. They are real, responsive, and consistent. Older mills are operated by most. Newer 5-axis gear is used by some. However, it's important that they measure bores, check threads, and halt work when something goes wrong. We observed a runout problem at 500 rpm in one job. The collet was switched by the operator. Repaired. No components were wasted. These teams operate in this manner.

They request drawings. Good ones. with exceptions. They examine the documents. If your thread note is missing or your hole size appears strange, they will call. That's excellent. This avoids errors. They provide actual lead times in their quotes. Not three-day dreams. If it's twelve days, they let you know and hold

Materials These Factories Commonly Use

- Aluminum (6061, 7075) - for housings, enclosures, sensor blocks

- Brass - for inserts, electrical fittings, soft load-bearing parts

- Stainless Steel (304, 316) - for brackets, bushings, harsh environments

- Plastics (Delrin, Nylon, PEEK) - for cleanroom, non-metal applications

- Carbon Steels - for structural, support, or tool components

Each material requires different speeds, feeds, toolpaths. These factories do not guess. They set the job right. One missed depth can wreck a run.

What to Look For in a Real CNC Partner

- They ask questions before quoting

- They reject bad drawings, not run them blind

- They track tool life

- They log offsets

- They hold tolerances from first to last part piece

- They send pictures, updates, and packing list

CNC machining is not magic. The machine does what it is told. Good shops program well. They run test cuts. They dry run new programs. And they stand next to the machine when it starts.

Real Problems, Real Fixes

One of these shops had a job where brass inserts were crushing during the knurl. They solved it by reducing pressure, preheating the brass, and changing knurl pitch. That came from experience.

Another had Delrin parts warping. They fixed it by slowing spindle speed and clamping with rubber pads. Saved the batch.

A shop in Ohio snapped a carbide end mill by plunging too fast into a steel plate. They replaced it, reran the path slower, and flagged that tool for special handling next time. That kind of knowledge does not come from reading manuals.

Why These Companies Made the List

Because they do not fake it. They ship parts that fit. They rerun when needed. They hold tolerances. They know their tools and machines. And they are honest when something needs fixing.

They are not resellers. They are builders.

Some run 3-axis only. Some do 5-axis work. But all of them can take your drawing and make it real.

Get CNC Parts That Actually Fit

If you need custom OEM cnc machining parts, enclosures, bushings, brackets, housings, and inserts made in the USA or Europe and built by real operators, then these are your companies.

No guesswork and outsourcing. Just real cuts, good threads, and jobs that run right.

Request a Free CNC Quote now.