Understanding a neutral bar starts with the neutral conductor. The neutral carries return current back to the source. The bar holds that conductor steady inside the panel. The job looks simple when you see the metal block, but the electrical behavior behind it is exact. The neutral point controls voltage balance across the system. It keeps the phases stable. It also locks the grounded reference so the equipment does not drift under load.

Industrial panels place heavy demand on the return path. A weak bar heats. A loose termination moves. Both conditions create noise in the system. A correct neutral bar holds each wire clean. It keeps the current where it belongs. It keeps the enclosure clear of load current. These basics protect every machine downstream.

The details matter. The material, the hole pattern, and the insulation method change with the rating of the panel. The choice of bar affects stability over years of service. A poor bar fails slowly. A correct bar stays tight. This guide covers the electrical role, the physical build, the sourcing decisions, and the installation checks that keep neutral systems safe.

Defining the Electrical Role of the Neutral Conductor

The neutral conductor carries return current back to the source. The neutral carries return current in single phase circuits and in any three phase system that is not perfectly balanced. This return path keeps the system stable. It holds the voltage at a known reference point. The neutral also gives the system a grounded point so the phases sit at the correct potential.

The neutral does not share the job of the ground. The neutral carries load current. The ground carries fault current only. The neutral is part of the working circuit. The ground bar is part of the safety circuit. This distinction drives how the neutral bar works inside every panel.

A neutral bar gives each neutral conductor a clean termination point. The bar keeps each conductor tight, stable, and isolated from the enclosure unless bonding is required. This isolation protects the grounding system from stray load current.

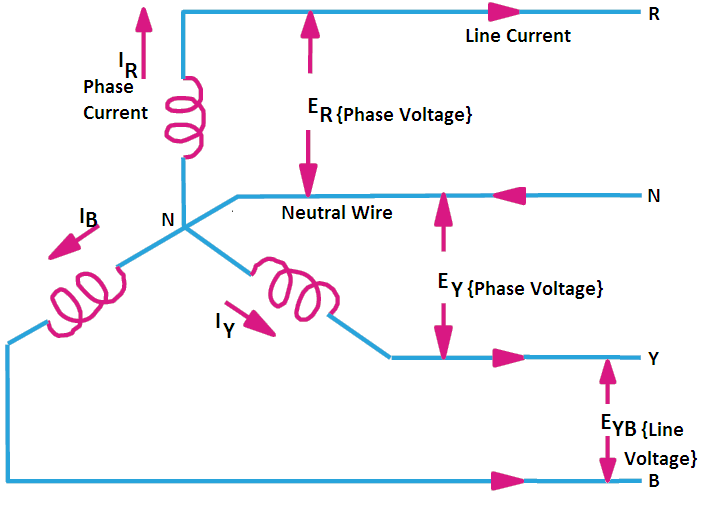

How Neutral Bars Manage Return Current in 3 Phase Systems

A three phase system does not always balance. Loads shift between phases. One phase may run heavy. Another may run light. The neutral bar handles these imbalances. The return current from each phase flows back through the bar. The current rises or falls as the loads move. The bar must hold each conductor tight so the return path stays stable.

If the three phases carry equal load, the neutral current approaches zero. If one phase pulls harder, the neutral current rises. The bar must manage this changing flow without heat or movement. Industrial equipment depends on this stability. A loose or weak bar creates noise, voltage drift, and early failure in downstream equipment.

The neutral bar must match the rating of the system. A light bar cannot handle the return current of a heavy load. A correct bar holds its shape, holds torque, and holds current without distortion.

Referencing Ground: Why the Neutral Point Is Bonded at the Service Entrance

The neutral bonds to the grounding system at one location only. That location sits at the service entrance. This bond sets the reference point for the entire system. The bond ties the neutral conductor to earth so the voltage stays fixed. Without this bond, the system floats. A floating system drifts and creates unsafe potential on exposed metal.

The single bond also gives fault current a direct path back to the source. The breaker trips because the fault rises fast. The bond must stay clean. The bond must stay tight. A second bond in a subpanel creates parallel paths. Parallel paths carry load current into the grounding system. That condition brings voltage onto the enclosure. The enclosure becomes unsafe.

Bonding at the service entrance stabilizes three phase distribution. It locks the reference. It keeps the neutral at the correct potential. It keeps the grounding system clear of load current.

The Physical Component: Specifications and Construction of the Neutral Bar

A neutral bar is a current-carrying block that terminates the neutral conductors inside the panel. The bar must match the electrical rating of the system. It must also hold torque without distortion. The design looks simple, but each feature exists for a reason. The hole pattern controls conductor size. The material controls heat rise. The insulation controls safety. Each part affects the behavior of the return path.

Most neutral bars use copper, brass and aluminum. Copper runs hotter without losing strength. Aluminum weighs less and costs less. Some bars use tin plating to slow corrosion and keep the contact surface stable over years of service. Brass neutral links appear in control panels with lower load. These links hold threads well, but they are not used for main service equipment because brass cannot carry high fault current.

The bar mounts on an insulated base when it sits in a subpanel. That base stops the bar from touching the enclosure. The bar mounts directly when it serves as the bonded neutral in a service entrance. The mounting screws must match the rating of the bar because the screws carry part of the mechanical load. A weak screw loosens under heat. A strong screw holds torque.

Hole sizing follows the conductor size on the drawing. Each hole takes one neutral conductor. Multi-wire terminations cause heat and movement. The spacing between holes protects the insulation of each conductor from cut or pinch points. The bar must match the number of circuits in the panel. A small bar starves conductors. A correct bar holds every termination clean.

A neutral bar is not a generic block of metal. It is a rated component with defined material, spacing, plating, and mounting rules. These details keep the return path stable across the life of the panel.

Isolation vs Bonding: Neutral Bars in Service Entrances and Subpanels

Neutral bars follow two different rules depending on where they sit in the system. The service entrance requires a bonded neutral. The subpanel requires an isolated neutral. This rule decides how current flows under load and under fault. It also decides whether the enclosure stays safe when a conductor fails.

A bonded neutral bar touches the panel enclosure through a bonding screw. This connection ties the neutral conductor to the grounding system at one point. That point sits at the service disconnect. It sets the reference for the entire building. It keeps the phases stable. It gives the fault a low resistance path back to the source so the breaker trips clean.

An isolated neutral bar sits on an insulated base. The mounting screws do not touch metal. The bar stays clear of the enclosure. This isolation stops load current from leaking into the grounding system. The return path stays on the neutral conductor only. This condition is mandatory in every subpanel. A second bond in a subpanel creates parallel paths. Parallel paths push load current into conduits, frames, and equipment cases. That condition brings shock risk.

The ground bar in a subpanel follows the opposite rule. It bonds directly to the enclosure so fault current moves with low resistance. The neutral never shares this job. The separation protects both systems. The neutral carries load current. The ground stands ready for a fault. Bonding and isolation keep these paths clean and predictable. This rule protects every circuit downstream.

Procurement and Quality Assurance: Selecting Neutral Bar Manufacturers

Sourcing a neutral bar looks simple until you check the details that control safety and long term stability. The bar must match the electrical rating of the panel. It must follow strict material and construction rules. A weak bar creates heat. A loose hole pattern cuts insulation. A poor finish builds resistance. These issues rise when the manufacturer does not follow a controlled process.

A supplier must provide the correct material. Copper and aluminum neutral bars must follow the grade listed in the panel schedule. Brass neutral links appear in control panels with light loads, but they are not suitable for service equipment. The supplier must list the grade, the plating, and the heat treatment. These points decide how the bar handles torque and current. A correct bar holds the conductor tight without creep or distortion.

Hole sizing and spacing must follow the drawing and the standard for the conductor size. Each hole takes one conductor. Multi-wire terminations create heat and movement. The bar must hold torque without stripping. The screws must match the mechanical load and the electrical rating. A correct supplier tests this on each batch and rejects any bar that moves under load.

Procurement must treat a neutral bar as a rated component. The cheapest bar creates the highest long term cost. A correct bar holds current, holds torque, and stays stable under load. This is the only path to a safe panel.

Installation and Safety: Common Mistakes to Avoid

A neutral bar fails when the installer makes small errors that stay hidden until the load rises. Each mistake changes the current path. Each mistake raises heat. Each mistake creates risk. The installer must follow strict steps to keep the return path stable.

Common mistakes:

- Mixing neutral and ground conductors in a subpanel. This creates a parallel path and pushes load current into the grounding system.

- Forgetting to isolate the neutral bar in a subpanel. The bar must stay clear of the enclosure unless it sits at the service entrance.

- Landing two neutral conductors under one screw. Each conductor needs its own hole to hold pressure evenly.

- Using a bar that does not match the panel rating. A light bar cannot handle heavy return current.

- Using screws that cannot hold torque. Weak screws move under heat and loosen the conductor.

- Damaging conductor insulation during stripping or insertion. A cut or nick creates a partial contact point that heats.

- Skipping torque checks on neutral screws. A loose screw changes resistance and causes temperature rise.

- Failing to confirm the single bonding point at the service entrance. A second bond creates dangerous circulating current.

These points keep the neutral path clean. These points keep the enclosure safe. These points protect every load downstream.

Request a Quote

Request a Quote for brass neutral bars, aluminum neutral links, and copper neutral bar built to your requirements. We supply Germany, the UK, Italy, the Netherlands, the USA, and global markets.