Aluminum CNC machining turns a design into a functional component. I see this every time a drawing moves from concept to the machine table. Aluminum cuts clean under high spindle speed. This behavior allows tight control over size and geometry.

An aluminum CNC services does more than remove material. The machinist controls tool selection. The machinist controls feed rate. The machinist controls heat buildup. These factors keep dimensions stable during cutting.

Design issues appear early during machining. Thin walls flex. Sharp corners load the cutter. Poor radii increase tool wear. CNC machining exposes these problems before production volume begins.

Modern aluminum CNC machining services support prototype work and repeat production. CNC turned parts define round features and concentricity. CNC milled parts form flats, pockets, and complex profiles. Both operations shape the final component.

This blog explains aluminum CNC machining from concept to sourcing. It focuses on process control, machine capability, and material behavior.

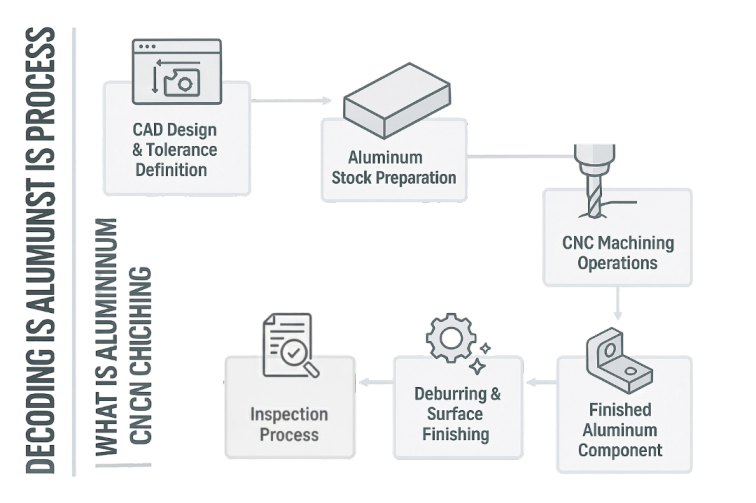

Decoding the Process: What is Aluminum CNC Machining?

Aluminum CNC machining starts with raw material in bar, plate, or billet form. The machinist selects the stock based on the part geometry and tolerance requirement. The material gets clamped into a fixture or chuck before cutting begins.

A CNC machine removes material using programmed tool paths. The cutter follows the design data to shape the part step by step. Aluminum allows high cutting speed without excessive tool wear. This makes the process efficient and predictable.

Different operations shape different features. CNC turning creates round profiles, bores, and concentric diameters. CNC milling forms flat surfaces, pockets, slots, and complex contours. The machinist chooses the operation based on feature geometry.

Inspection follows machining. Critical dimensions get checked during and after the run. This confirms that the part matches the drawing before it moves forward.

The result is a finished aluminum component ready for assembly or further processing.

Defining the Modern Aluminum Machining Service

A modern aluminum machining service uses advanced machine capability to reduce setups. Multi-axis CNC machines cut multiple faces in a single cycle. This improves accuracy on complex geometry and reduces handling error.

5-axis machining allows access to angled features and deep pockets. The part stays clamped while the machine changes orientation. This protects datum alignment and improves positional accuracy. Older 3-axis setups cannot do this efficiently.

Modern services also rely on advanced CAM programming. The toolpath adapts to aluminum cutting behavior. This controls chip load and heat buildup. Stable cutting protects surface finish on thin walls and fine details.

Automation supports consistency. Tool length measurement, probing, and in-process verification reduce manual intervention. These systems catch deviation early and keep parts inside tolerance.

This combination defines modern aluminum machining. Capability replaces guesswork. Complex parts move from design to finished component with fewer corrections.

Is it Aluminium CNC Machining or Aluminum?

Both spellings refer to the same metal. The difference comes from regional usage. The United States uses “aluminum.” The United Kingdom and Europe use “aluminium.”

Search behavior follows this pattern. USA buyers type aluminum CNC machining service. UK buyers search aluminium CNC machining. A technical discussion stays the same regardless of spelling.

The machining process does not change. The cutters do not care about spelling. Only the market language does.

Why Aluminum Performs Best in CNC Machining

Aluminum performs well in CNC machining because it cuts predictably. The material forms clean chips under sharp carbide tools. This behavior reduces cutting force and limits tool wear. Stable cutting allows higher spindle speed without losing control.

Thermal behavior also matters. Aluminum dissipates heat faster than many steels. This reduces heat concentration at the cutting edge. Lower heat keeps dimensions stable during long machining cycles.

Weight plays a role. Aluminum has low density compared to steel. This reduces inertia during rapid axis movement. Faster acceleration improves cycle time without sacrificing accuracy.

Material consistency supports repeatability. Common grades used in aluminum machining service show uniform structure. This consistency helps hold size across multiple batches. That reliability makes aluminum suitable for both prototypes and production runs.

These properties explain why aluminum remains a preferred material in CNC machining environments.

The Role of the Aluminum CNC Machine in Achieving Tight Tolerances

The machine defines how well aluminum holds tolerance. A rigid aluminum CNC machine resists vibration during high-speed cutting. Reduced vibration protects surface finish and dimensional accuracy.

Spindle speed capability matters. Aluminum benefits from high RPM cutting. A machine built for this range keeps the cutter engaged smoothly. Smooth engagement prevents chatter on thin walls and fine features.

Axis precision controls feature location. Linear guides and ball screws must stay tight. Accurate positioning keeps hole spacing and profile geometry inside tolerance limits. Any backlash shows immediately in aluminum parts.

Modern machines support probing and tool measurement. Probing verifies part position before cutting. Tool measurement keeps cutter length consistent. These systems reduce manual error and support tight tolerance work.

The machine and the material work together. Aluminum responds well when the machine stays stable. That combination produces accurate parts without excessive correction.

From Design to Machining: The Aluminum CNC Workflow

The aluminum CNC workflow starts before any material touches the machine. The first step is design intent review. The machinist checks whether the geometry matches aluminum cutting behavior. This review prevents problems that appear later on the shop floor.

Design features drive machining success. Deep pockets increase tool load. Thin walls flex under cutting force. Sharp internal corners trap tools. These risks get identified during workflow planning, not during cutting.

The workflow also defines how the part will be held. Fixturing strategy affects accuracy and repeatability. A stable setup reduces vibration and keeps datum alignment consistent. Aluminum allows fast machining, but poor setup still causes failure.

Toolpath planning completes the workflow. The programmer selects cutting direction and step-over based on aluminum chip formation. This planning controls heat, surface finish, and dimensional stability. When the workflow is correct, machining becomes predictable.

This workflow bridges design and production. It turns a drawing into a part that machines clean without correction.

Design Optimization for the Aluminum CNC Machining Service

Design optimization adapts the model to aluminum machining limits. Wall thickness must support cutting force without deflection. Thin sections need reinforcement or adjusted geometry.

Corner radii matter. Larger internal radii reduce tool stress and improve surface finish. Small radii increase cycle time and tool wear. Aluminum allows flexibility, but geometry still sets limits.

Hole depth and diameter require balance. Deep holes need stable length-to-diameter ratios. Poor ratios cause chatter and drift. Adjusting depth improves accuracy and tool life.

Tolerance selection also affects machinability. Tight tolerances increase machining time and inspection load. Realistic tolerances keep cost and lead time under control. Aluminum holds tolerance well, but only when the design allows it.

Surface finish choices complete the optimization. Fine finishes need lighter cuts and stable paths. Early decisions here prevent rework later.

Strategic Sourcing: Finding an Expert Partnership

Strategic sourcing in aluminum CNC machining goes beyond unit price. Low quotes often hide weak process control, unstable scheduling, and poor communication. These gaps show up later as rework, missed deadlines, and inconsistent parts. A short-term saving turns into a long-term cost.

An expert partnership changes that outcome. A capable partner reviews the design before cutting. The partner flags risk early and stabilizes the process. This approach protects tolerance, surface finish, and delivery when volumes increase. The value comes from repeatability, not promises.

A true partner supports the full lifecycle. The shop handles prototypes and scales production without changing behavior. The team communicates directly and documents the process. This keeps each order aligned with the last one.

We operate as that partner. We run controlled aluminum CNC machining services with disciplined workflows and direct engineering support. We machine to requirement and hold consistency across batches. Hiren Brass Products work as part of your supply chain, not a one-off vendor.

If you need a reliable aluminum machining service that supports growth without surprises, start the conversation.