Aluminum CNC machined parts are widely used because the material is lightweight and machines efficiently. Aluminum allows higher cutting speeds and reduced cycle time when compared with harder metals.

Modern manufacturing also demands flexibility. Companies need custom parts that move from design to machining without long delays. CNC machining supports this by allowing fast adjustments and repeatable results.

This article explains why demand for aluminum CNC parts keeps growing and what manufacturers should consider when moving from concept to full production.

Understanding the Market: Why Aluminum CNC Parts are in Demand

Manufacturers use aluminum more today because it solves practical. The material is light, which helps reduce overall product weight. It also keeps good strength for many industrial uses.

Aluminum cuts faster than steel in CNC machines. Higher cutting speed reduces cycle time. Lower cutting force also helps keep tools stable. This makes production easier when repeatability matters.

Corrosion resistance adds another reason. Many parts work in environments where rust creates failure risk. Aluminum handles these conditions without heavy coatings.

Demand grows because the material fits modern manufacturing needs. Engineers want parts that are light, accurate, and practical to machine. Aluminum meets this balance better than many alternatives.

Understanding the Scope of Custom CNC Aluminum Parts

Custom CNC aluminum parts are made to a specific drawing. They are not standard catalog items. The design comes from the customer’s requirement.

The scope includes parts that need precise dimensions and repeatable machining. These parts often fit into assemblies where alignment and accuracy matter. Function decides the shape, not appearance.

Custom work usually involves low volume and repeat batches. Designs may change during development. CNC machining supports these adjustments.

Typical parts include spacers, adapter, brackets, mounting blocks, fixtures, and supports. Each part exists to solve a specific engineering need. The scope stays focused on function, precision, and repeatability.

From Concept to Reality: The Prototyping Phase

Designs look correct on a screen, but real problems appear only after machining. Prototypes turn design ideas into physical parts that engineers can test. This step shows whether the part actually works in assembly.

Engineers can change the design and machine a new part quickly. This shortens development time and reduces risk before production starts.

The prototyping phase also reveals manufacturing limits. Thin walls may bend. Features may be difficult to machine. Assembly alignment may fail. Fixing these issues early prevents expensive mistakes later.

The Critical Role of the Aluminum CNC Prototype

An aluminum prototype allows real testing. Engineers check fit, alignment, and movement inside the assembly. Problems become visible immediately when parts do not match design intent.

Material behavior also becomes clear during testing. Aluminum may flex, vibrate, or wear differently than expected. These results help engineers adjust the design based on real performance.

Prototypes reduce uncertainty. They confirm whether dimensions, tolerances, and surface finish meet functional needs. This step builds confidence before moving forward.

Transitioning from CNC Aluminum Part Design to Full-Scale Production

Production does not start the moment a prototype works. The design usually needs small adjustments for stable machining. Features may change to improve tool access or reduce cycle time.

Process stability becomes the main focus. The goal shifts from proving the design to repeating it consistently. Toolpaths, fixtures, and inspection methods must support repeat production.

Standardizing the design helps avoid variation between batches. Once the process becomes stable, the part moves into regular manufacturing with lower risk and better reliability.

Advanced Machining: Specialization in Turning and Milling

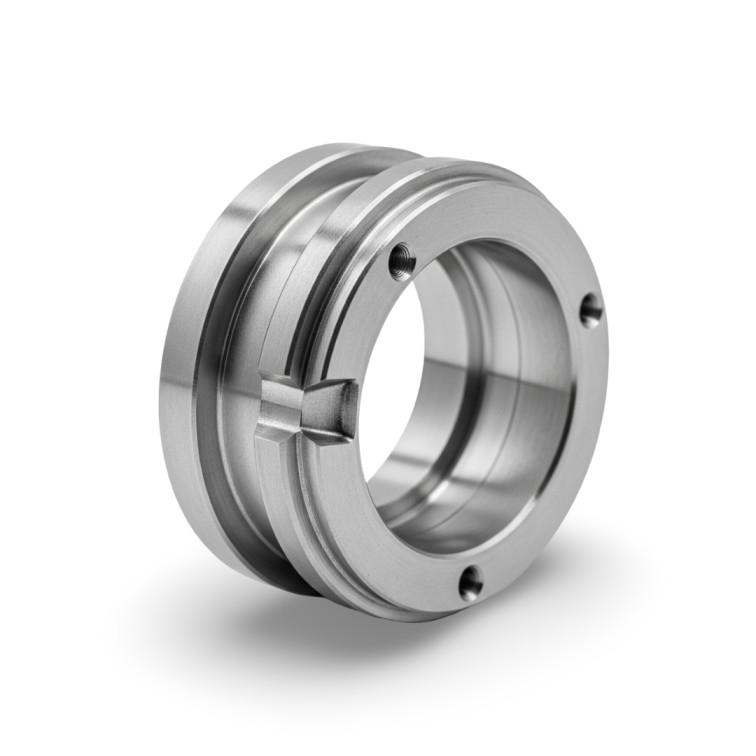

Aluminum parts often need more than one machining process. Milling creates flat faces, slot patterns, and mounting features, which are common in components like aluminum neutral bar. Turning creates round features and controls concentric dimensions. Many parts need both methods to reach final geometry.

Process selection depends on the part design. Milling handles multi-face features and precise positioning. Turning handles shafts, diameters, and threaded sections. Using the correct process reduces error and improves repeatability.

Setup planning matters when switching between milling and turning. Poor setup introduces alignment problems between features. Stable fixtures and accurate datums keep the part consistent through both operations.

Aluminum reacts quickly to cutting conditions. Heat, chip removal, and tool sharpness influence surface finish. Skilled machining controls these factors to avoid deformation and maintain accuracy.

Specific Considerations for Machining Aluminum CNC Turning Parts

Aluminum turns easily, but high speed increases vibration risk. Chatter damages surface finish and dimensional control. When this happens, the final CNC turned parts fail quality expectations.

Sharp tools are critical for clean cutting. Dull edges smear the material instead of cutting it. This increases heat and affects dimensional control.

Concentricity becomes a main concern in turning operations. Any setup error shows immediately in rotating parts. Proper chucking and support reduce runout and keep diameters true.

Chip control also matters. Aluminum produces long chips at high speed. Poor chip evacuation can scratch surfaces. Stable process control keeps the operation clean and repeatable.

Evaluating Quality and Manufacturer Standards

Quality matters because prototype success means nothing if production changes later. A reliable manufacturer keeps the same result across every batch. Consistency protects assembly performance and reduces field failures.

Inspection must happen during production, not only at the end. Early checks catch drift before scrap increases. This keeps dimensions stable and prevents hidden problems.

Repeatable setups also define quality. When fixtures and processes stay stable, parts stay consistent. Random setup changes create variation even when the design is correct.

Documentation supports long-term reliability. Inspection records and process notes help maintain repeat results. Traceability allows problems to be identified quickly when changes appear.

Assessing Quality Assurance for CNC Aluminium Parts

Dimensional inspection confirms whether the part matches the drawing. Critical features such as hole location, flat surfaces, and mating areas need regular verification. Measuring these during the run prevents batch-wide errors.

Surface finish checks matter for contact areas. Rough finishes increase friction and reduce performance. Consistent finishing keeps the part functional across multiple runs.

Position and flatness checks protect assembly accuracy. Small alignment errors cause bigger problems when parts come together. Proper inspection prevents this risk.

First article inspection verifies that the setup is correct before production continues. This step reduces waste and gives confidence that the process is stable. Repeat checks during production confirm consistency from start to finish.

The Value of Material Expertise in Custom CNC Aluminum Parts

Different aluminum grades behave differently during machining. Some grades cut easily while others create more tool wear. Understanding this difference prevents unstable results.

Heat behavior also changes with material choice. Certain grades hold heat longer and affect dimensional stability. Skilled machinists adjust cutting strategy to control this effect.

Grade selection must match the application. A structural part may need higher strength. A lightweight support may require easier machinability instead. Choosing wrong material creates defects even when machining is correct.

Material expertise reduces risk. It prevents surface issues, dimensional drift, and unexpected failures. That knowledge separates experienced manufacturers from general shops.

Selecting a Reliable Manufacturing Partner

Choosing a manufacturing partner affects long-term production stability. A good supplier does more than machine parts. The supplier helps maintain consistency from prototype to repeat batches.

Communication is one of the first signs of reliability. A serious manufacturer reviews drawings carefully and asks clear questions before machining starts. This prevents mistakes that appear later during production.

Process stability also matters. The same setup and inspection method must continue across future orders. If the process changes every time, part quality will change as well. Reliable partners control this variation.

Experience with aluminum machining makes a difference. The manufacturer must understand how aluminum behaves during cutting and clamping. This knowledge helps avoid deformation, surface issues, and tolerance drift.

A strong partner supports development and production together. The goal is not just to deliver one batch. The goal is to build repeatable results that support your manufacturing needs over time.