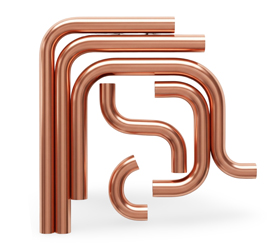

Copper tube bending is a process that shapes plain copper tubes into working parts for HVAC and heat-pump systems. The tube keeps its wall strength and smooth inner surface during bending. U bends, L bends, and tight 90-degree turns are made to match each layout.

Work begins with raw copper tubing. It passes through a bending die where the radius, angle, and length follow the drawing. Each bend fits the next fitting cleanly, keeping the flow line open for refrigerant.

These bent tubes run through suction lines, defrost paths, and suction assemblies. German buyers use them in chillers and compact heat pumps. The result is neat routing, fewer joints, and steady performance over time.

Request a Free Copper Tube Bending Quote today and get custom bends made to your exact drawing.

OEM copper tube L-bend produced strictly to customer drawing requirements. Manufactured from Cu 28 × 1 mm copper tube with a controlled 90-degree bend and fitted with a G 1-1/4 brass nut. Supplied to HVAC heat pump and chiller manufacturers for copper pipe routing in fluid circulation assemblies.

OEM copper tube bend manufactured from a customer-supplied sample. Produced with controlled bending and a 3/8 threaded brass nut connection as required by the buyer. Supplied to manufacturers of central heating radiators and boiler equipment for custom assembly requirements.

Fabricated copper tube and flange assembly produced according to approved technical drawing. Manufactured from 1/4 inch copper tube with controlled 90° and 135° bends and a welded copper flange connection. Supplied for HVAC and refrigeration equipment where precise tube routing and rigid flange mounting are required.

Refrigeration service valve assembly manufactured using 1/4 inch copper tube with an integrated bent tube section. The copper tube is formed to a controlled radius and brazed to the service valve body for HVAC and refrigeration charging, servicing, and testing access points. This component represents OEM fabrication of refrigeration access valve assemblies with copper tube bending.

Our custom copper tube bending service covers all shapes used in HVAC, refrigeration, and heat-pump systems. Each bend follows the customer drawing, with wall thickness, radius, and angle.

Common in condensers and evaporator coils. Formed with a smooth radius so refrigerant flows evenly between tubes. Keeps uniform wall thickness and accurate spacing for coil assembly.

Used in suction and discharge lines. Each bend holds a clean angle without flattening. Saves time during brazing and keeps air-conditioning layouts compact.

Ideal for tight corners and compact coil returns. Produced to match jig dimensions and verified for angle precision. Reduces leakage points in multi-pass systems.

Continuous copper coil bending for heat recovery, defrost, & chiller loops. Maintains roundness along the full length and stable spacing between turns.

Copper suction line bending keeps pressure loss low and flow unrestricted. Copper defrost line bending withstands frequent heating and cooling cycles without fatigue cracks.

Copper tube bending need control, technique, not force. Each bend follows a measured process to keep shape and flow intact. Operators start with annealed copper, soft enough to form without cracks. Tubes feed through rotary-draw machines where every radius, length, and angle matches the drawing.

Tooling is selected per diameter. For tight bends, an internal mandrel supports the wall to prevent flattening. Large coils use rotary bending to keep even curvature across the run. Every batch is measured for tolerance and roundness before release.

We handle prototypes, small lots, and OEM quantities using the same inspection routine. Each part reflects true kundenspezifisches Kupferrohr Biegen, tailored to the German HVAC industry.

Copper tube bending connects every part of a cooling and heating circuit. Each bend keeps refrigerant flow smooth, reduces joints, and prevents leaks.

In copper tube bending for HVAC systems, tubes link the condenser, evaporator, and compressor in split and central units. Each bend maintains roundness and stable flow, helping installers route lines neatly through tight service spaces.

Our copper tube bending for heat pumps ensures precise routing of suction, discharge, and defrost lines. It helps achieve compact layouts and higher thermal efficiency. German OEMs choose these bends for clean assembly and minimal leak points.

Copper tube bending for refrigeration lines is used in chillers, cold rooms, and display cabinets. Consistent bend geometry prevents stress cracking and keeps temperature control accurate even under continuous load.

Bent copper tubes also serve in dehumidifiers, heat exchangers, and industrial cooling skids. Each piece is formed to print and pressure-tested before shipment.

Kupferrohr Biegen für Wärmepumpen - relied on by German and European system builders for precise assembly and long service life.

Copper tube bending for OEM production requires repeatability, traceable materials, and steady delivery. Our facility handles both short prototype runs and high-volume batches with the same level of control. Each job starts with verified copper tubing and ends with full inspection data. Dimensional checks, surface finish, and wall roundness are recorded before dispatch.

We work as an OEM copper tube bending supplier for HVAC and heat-pump manufacturers across Germany and Europe. Every shipment includes labeling, protection caps, and export-ready packaging. Production schedules are planned around customer forecasts to maintain uninterrupted assembly lines.

| Parameter | Description | Why It Matters |

|---|---|---|

| Production Type | OEM copper tube bending, prototypes to mass batches | Confirms capacity for both small and large orders |

| MOQ | From 100 pcs to full OEM volumes | Supports sampling, validation, and production |

| Lead Time | 2-4 weeks standard, expedited on request | Keeps OEM schedules on track |

| Documentation | Material certificate, inspection report, PPAP on request | Meets German and EU quality standards |

| Tolerance Control | ±0.3 mm angle, ±0.5 mm length | Ensures clean fit and brazing alignment |

| Packing & Labeling | Cleaned, capped, export cartons & crates, pallets | Prevents contamination and transport damage |

| Shipping | Regular routes to Germany, Europe, and global ports | Simplifies logistics for long-term supply contracts |

Kupferrohr Biegen Deutschland - trusted by OEM buyers for consistent quality and reliable lead times.

Yes. Send your 2D or 3D drawing in PDF, STEP, and DWG format. Our engineers review radius, wall thickness, and tooling before production. We confirm bend feasibility and share a sample if required.

Yes. We regularly supply copper suction line bending and copper defrost line bending for HVAC and heat-pump systems. These tubes are tested for roundness and leak resistance.

Typical tolerance is ±0.3 mm on angle and ±0.5 mm on leg length. We can meet tighter tolerances for OEM projects that need first-article inspection.

Each tube is internally cleaned, ends are capped, and bends are packed in export cartons & wooden crates. This prevents dust, oxidation, and damage during transport to Germany and the EU.

Yes. We support prototype or pre-series runs starting from 100 pieces. Once dimensions are approved, the same setup is used for full OEM batches.

We can issue material certificates, dimensional inspection reports, and documentation when required by German and European OEMs.

Main sectors include HVAC, heat pumps, refrigeration, solar thermal, and chillers. We also bend copper tubes for dehumidifiers, heat exchangers, and industrial cooling systems.

Send your drawing, or sample we will review the bend radius, diameter, and layout, then suggest the best forming method. Each order follows your specifications, from prototype to full OEM production.

Our team supplies German and European buyers with consistent bends, clean finishes, and export-ready packaging. You get technical support, inspection reports, and dependable delivery every time.

Request a Free Copper Tube Bending Quote today and get a quick response from our team.