Neutral bars keep electrical circuits stable. They connect the neutral and ground wires safely inside the panel. Used in control panels, switchgear, and distribution boxes.

We make three main types. Brass neutral bar for strong threads and corrosion resistance. Aluminum neutral bar for lightweight systems. Copper neutral bar for high current capacity.

Each bar is machined clean, drilled straight, and tested before dispatch. Also available as neutral links and ground bars for standard and custom panels. Supplied across Spain and Europe.

Request your quote today for OEM and bulk supply. Trusted by buyers searching for barra neutra latón in Spain.

Neutral bars come in several material grades and dimensions. Each bar is cut, drilled, and finished to match control panel standards. Every unit passes thread and flatness inspection before packing.

| Specification Type | Details |

|---|---|

| Material Options | Brass – corrosion resistant and durable. Copper – high conductivity for heavy load. Aluminum – light weight, cost-efficient. |

| Typical Cross Sections | Custom Size as per requirements and drawing |

| Thread Sizes | M4, M5, M6, M8 (other sizes on request) |

| Surface Finish | Natural, nickel plated, or tin plated |

| Inspection Parameters | Flatness, hole alignment, thread gauge, surface finish |

| Mounting Options | Insulated bases, brackets, or direct panel fit |

Each barra colectora neutra de latón or enlace neutro is checked for proper spacing and thread quality. Ground bar versions can include mounting insulators for added safety.

Solid copper neutral bar manufactured with accurately drilled through holes and clean machined edges. The image reflects multiple bar lengths produced within the same batch, showing customization for different circuit counts and layouts used in electrical control panels and distribution board assemblies..

Extended-length brass neutral bar produced from solid brass stock with a visible machined surface. The bar is manufactured with 24 inline threaded terminal positions and four separate mounting holes to support stable installation. A stepped section is present at the center of the bar. This configuration is used in electrical control panels, distribution boards, and OEM assemblies where a larger number of neutral connections are required.

Machined brass neutral bar featuring 15 inline M3 threaded terminal points for conductor termination. The bar is supplied assembled with MS combination head screws and includes two side holes of different sizes for mounting. The brass body is evenly machined and intended for use in electrical control panels.

Custom Brass neutral bar produced with a tin-plated surface and machined to include 15 inline M4 threaded terminal holes. The bar shows a consistent matte tin finish with accurately machined faces and even terminal spacing. Two larger side holes are incorporated for mounting. This configuration is used in electrical distribution boards and control panel assemblies where a tin-coated brass conductor is specified.

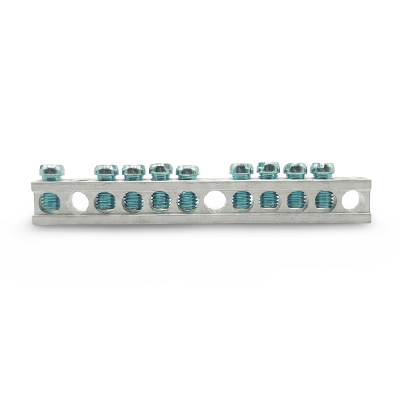

Aluminum neutral bar has an overall length of approximately 95 mm and a height of about 12.5 mm, with 12 machined holes in total, including three dedicated mounting locations. The bar is supplied assembled with blue-coated clamping screws and is used for conductor termination in electrical distribution boards and industrial control panel assemblies.

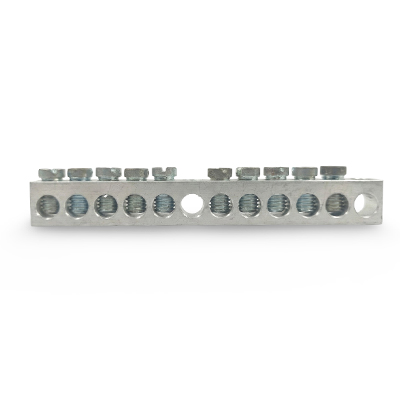

Aluminum neutral bar manufactured for electrical distribution applications. The bar is 12 threaded circuit terminals with 10.05 mm center spacing. Two threaded mounting holes are provided for installation. Designed to accept 2–14 CU conductors, the bar is supplied assembled with combination head screws and is used in panelboards and industrial control cabinet assemblies.

The choice of material defines current capacity, durability, and long-term stability. Each barra neutra type serves a specific purpose in electrical distribution and control systems.

| Material Type | Key Properties | Typical Use |

|---|---|---|

| Brass Neutral Bar | Medium conductivity, strong threads, excellent corrosion resistance. | Standard electrical panels, terminals with frequent assembly. |

| Copper Neutral Bar | Highest conductivity, stable under high current, minimal heat rise. | Heavy-duty switchgear, high-power circuits, industrial bus systems. |

| Aluminum Neutral Bar | Lightweight, economical, good performance when space & cost is critical. | Large control boards, HVAC units, power distribution cabinets. |

| Tinned Finish Option | Added corrosion protection, stable resistance over time. | Outdoor & high-humidity installations. |

All materials are verified for conductivity and mechanical integrity before dispatch. Testing includes visual inspection, resistance measurement, and surface finish check.

Each neutral bar is produced under controlled machining standards. Precision starts from raw material selection and continues through every process.

CNC drilling ensures clean holes and consistent spacing. Threads are cut using calibrated taps to maintain fit accuracy. Tolerances are verified with gauges before plating.

We supply OEM and custom designs based on technical drawings or samples. Hole layout, bar length, and mounting type can be adjusted as required. Nickel and tin plating is available for corrosion protection and smooth electrical contact.

Sample pieces are usually prepared for first-off approval before bulk production. Production batches are serialized for traceability and inspection records.

| Custom Option | Specification Range |

|---|---|

| Hole Diameter | M4 to M8, or per drawing |

| Bar Length | 50 mm to 1000 mm |

| Mounting Type | Bracket, insulated base, or plain |

| Finish Type | Natural, nickel plated, tin plated |

| Tolerance Check | ±0.05 mm hole spacing, ±0.02 mm thread pitch |

All manufacturing follows ISO inspection standards. Each bar leaves the factory verified for thread depth, spacing, and surface finish.

Neutral bars provide a common connection point for neutral and grounding conductors. They keep electrical systems safe and balanced. Each material type is selected according to current load, panel design, and operating environment.

Used as the main neutral termination point in power and automation panels. Ensures safe return paths for circuits and stable voltage balance.

Mounted inside distribution enclosures to connect multiple neutral wires. Brass and copper types handle higher current capacity, keeping temperature rise within IEC 61439 limits.

Copper neutral bar preferred in switchgear due to its high fault-current tolerance and low resistance. Helps maintain circuit protection coordination under heavy loads.

Aluminum neutral bar often used in HVAC and large power cabinets. Lower weight supports compact design and easier mounting without sacrificing conductivity.

Neutral link and ground bar work together to connect the neutral line with the earth bus, improving fault safety. Complies with grounding standards used in European electrical installations.

All materials and finishes comply with RoHS and CE marking requirements for export to Spain and the EU.

| Application Type | Recommended Material | Typical Current Range | Standard Reference |

|---|---|---|---|

| Control Panel | Brass | Up to 125 A | IEC 60947-7-1 |

| Distribution Board | Copper | 125–250 A | IEC 61439 |

| Switchgear | Copper | 250–600 A | IEC 61439-2 |

| HVAC / Power Cabinet | Aluminum | Up to 150 A | EN 60204-1 |

| Grounding Bar | Brass or Copper | As per system design | IEC 60364 |

Neutral bars are supplied for OEM, bulk, and wholesale orders. Each shipment follows export packing standards and is tracked until delivery. Orders can include mixed materials or custom sizes under one purchase order.

| Order Type | Description |

|---|---|

| MOQ (Minimum Order Quantity) | Lower MOQ available for prototype and testing batches. |

| Lead Time | 2-4 weeks depending on quantity and plating type. |

| Packaging | Each bar individually wrapped to prevent thread damage. Packed in export-grade cartons with part labels and inspection codes. |

| Shipping Options | Air freight for small lots, sea shipment for bulk orders. Fast dispatch to Spain and Europe. |

| Order Support | Technical drawings reviewed before production. OEM labeling and documentation available. |

Our logistics team works directly with freight partners to maintain delivery accuracy. Each carton includes inspection data and batch traceability.

Yes. We produce directly from customer drawings or samples. Hole spacing, bar length, and thread size are matched exactly. A CAD drawing or PDF layout helps ensure perfect alignment during production.

Each batch passes dimensional inspection for hole diameter, spacing, and thread depth.

Yes. Every shipment includes a material test certificate (MTC) and inspection report. Certificates list conductivity values, plating thickness, and visual inspection data.

Yes. Neutral link bars with threaded holes or mixed thread types (M4–M8) can be machined as per drawing.

Yes. One or two sample bars are produced for fitting and dimension confirmation before full batch machining. Once approved, bulk manufacturing starts using the verified setup.

Production follows ISO dimensional inspection and RoHS compliance for plating. All measuring tools are calibrated, and inspection data is archived for traceability.

Every neutral bar leaves the factory tested and verified for size, conductivity, and surface finish. Products are packed for export and labeled for traceability. Our team supports OEM, custom, and bulk supply for Spain and Europe.

Send your technical drawing to request a quote. Orders for >barra neutra latón, barra neutra aluminio, and barra neutra cobre receive quick response.

Request your free Neutral Bar quote today.