CNC machining parts are built for exact function. Every components must match the drawing and hold tolerance. That is the standard expected in Germany and Europe.

Our production covers aluminum, brass, stainless steel, bronze, copper, and carbon steel. Every metal behaves differently on the machine. Feeds, tools, and cutting fluids are adjusted for each job to maintain accuracy and surface finish.

Our parts are made for direct use in OEM assemblies and industrial systems. Orders often include prototypes, small batches, and bulk high volume runs. Dimensional checks and surface inspections are part of every batch release.

CNC machining is not only about cutting metal. It is about consistency across thousands of parts. That is what we supply.

Request a quote for custom OEM and bulk quantity, our precision CNC parts made for your production line.

CNC machine parts are components produced by computer-controlled milling and turning. Each part is designed to meet exact specifications. Accuracy, finish and repeatability are the main requirements.

We handle both CNC milling parts and CNC turning parts. Milling is used when flat surfaces, slots, and complex geometries are needed. Turning is applied for cylindrical parts, threads, and shafts. Each metal requires specific tooling, speeds, and feeds to maintain precision.

Quality checks are performed at every stage. Dimensional inspection, thread verification, and surface finish measurement ensure that parts meet industrial standards.

German buyers can rely on suppliers for consistent output. CNC Frästeile Deutschland and CNC Drehteile Deutschland are available across multiple metals and grades. OEM components follow the same control measures as bulk orders.

CNC machining parts are not limited to one sector. They are used in automotive assemblies, electronics housings, industrial machinery, and tooling. Every project demands exact specifications, repeatable quality, and reliable delivery schedules.

We support a wide range of metals for CNC machining. Here are some of the common materials we work with. Each metal has unique properties. Selection depends on strength, corrosion resistance, conductivity, and machinability. Every metal requires specific tooling and feeds to maintain precision. Proper selection ensures long-lasting, reliable and smooth CNC machining parts bulk production. German buyers can rely on a Präzisions-CNC-Teile Hersteller for consistent quality and delivery.

CNC machined Aluminum Parts are lightweight and corrosion-resistant. Also aluminum is very cost saving material. Common grades include 6061 and 6063. 7075 is available for high-strength applications. Aluminum is ideal for housings, enclosures, and prototype components.

CNC machined brass parts provide clean threads and good wear resistance. Brass know for its machinability and straight. C36000 and C37700 are standard. Brass is widely used in fittings, connectors, and decorative components.

CNC stainless steel parts resist corrosion and maintain strength at high temperatures. Common grades include SS304 and SS316. Stainless steel is suitable for industrial tools, valves, and assemblies exposed to moisture.

CNC machined steel parts offer high strength and durability. Carbon steel and alloy steel are commonly used for structural components, shafts, and mechanical parts.

CNC machined copper and bronze parts are ideal for conductivity, and low-friction applications. Bronze is commonly used in bushings and wear components.

CNC-turned brass component designed as a precision sleeve with stepped geometry and a machined flange, produced for custom OEM applications and commonly referred to in Germany as CNC-gedrehte Messingbuchse nach Maß.

Custom CNC-turned stainless steel (SS304) hex stud featuring an M8 × 1.25 external thread and precision-machined hex flats, manufactured for OEM fastening applications and commonly referred to in Germany as CNC-gedrehter Edelstahl-Gewindestift.

OEM CNC-turned EN31 steel shaft with an overall length of 16 inches, featuring a stepped profile and pointed end, manufactured for heavy-duty testing applications requiring high strength and wear resistance, and commonly referred to in Germany as CNC-gedrehte EN31-Stahlwelle.

OEM copper CNC-turned sleeve with a stepped profile and precision internal bore, manufactured for use as a custom spacer in mechanical and industrial assemblies, and commonly referred to in Germany as CNC-gedrehte Kupferbuchse nach Maß.

Custom CNC-milled aluminum mounting bracket featuring a precision bore and black anodized finish, manufactured for secure mounting applications, and commonly referred to in Germany as CNC-gefräste Aluminium-Montagehalterung.

CNC-milled bronze component machined to a defined profile with precision drilled holes, manufactured for OEM mechanical assemblies, and commonly referred to in Germany as CNC-gefrästes Bronzebauteil nach Maß.

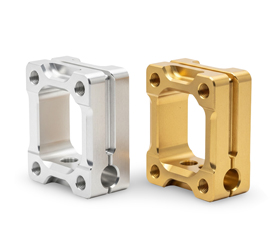

OEM brass CNC-milled block machined from solid brass stock with multiple drilled and tapped holes on perpendicular faces, finished with chrome plating for improved wear resistance and corrosion protection, and commonly referred to in Germany as CNC-gefräster Messingblock nach Maß.

OEM CNC-machined aluminum part produced using combined turning and milling operations, featuring precision bores and drilled holes for accurate assembly requirements, and commonly referred to in Germany as CNC-bearbeitetes Aluminiumbauteil nach Maß.

We manufacture custom OEM CNC parts according to customer requirements. Here are a few representative products we produce for various industries.

CNC machined parts are used across multiple industries and applications. Precision and durability make them ideal for both prototype and mass production needs.

CNC turning parts and CNC milled parts are widely used in automotive assemblies. Shafts, spindles, housings, and brackets ensure reliable operation in engines, transmissions, and suspension systems.

Hydraulic components, valve bodies, pump housings, and mechanical assemblies rely on CNC turning and milling for tight tolerances and consistent quality. These parts perform under high stress and continuous use.

Enclosures, heat sinks, RF casings, and mounting brackets are CNC milled or CNC turned to precise specifications. Aluminum and copper are often used for conductivity and thermal performance.

Jigs, fixtures, and custom tooling adapters are machined for assembly lines and manufacturing setups. CNC precision ensures repeatability, alignment, and safety.

Small-batch CNC parts, custom designs, and specialized brackets and fittings are produced to exact customer requirements. Materials include aluminum, brass, steel, stainless steel, copper, and bronze, depending on application needs.

As a trusted CNC Frästeile Deutschland provider, we deliver high-quality CNC turning parts and CNC milled parts for OEMs and industrial buyers. Our expertise covers both custom prototypes and bulk orders, ensuring precision, tight tolerances, and reliable material performance.

We also offer wholesale CNC parts and export services from Germany to Europe, catering to industrial clients who need large quantities with consistent quality. As an experienced OEM CNC components manufacturer Germany, we handle everything from small-scale production to large-volume deliveries, supporting your project requirements efficiently.

Lead times vary depending on complexity, material, and order quantity. For prototypes, we can often deliver within 1-2 weeks, while larger production runs may take 3-6 weeks.

Yes, we manufacture custom CNC aluminum components for OEM projects as per requirements, maintaining precise tolerances and high-quality surface finishes.

We work with aluminum, brass, steel, stainless steel, copper, and bronze. Custom grades and alloys are available on request.

Yes, our facility handles both CNC turning and milling, including combined turn/mill components for complex geometries.

Yes, we can handle single-piece prototypes, low-volume production, and large OEM orders with consistent quality.

All parts undergo dimensional inspection, material verification, and surface finish checks. Inspection reports are available on request.

Yes, we can provide threaded holes, tapped components, anodized finishes, and other custom surface treatments based on your specifications.

Yes, you can submit your inquiry for bulk quantity special pricing, and we provide prompt, competitive quotes.

We deliver precision turned and milled parts with strict attention to tolerances and material grades, ensuring your components meet exact specifications. Our team manages lead times efficiently, whether for prototypes, small batches, or large production runs.

With experience in aluminum, brass, steel, stainless steel, copper, and bronze, we support a wide range of industries and applications. As a trusted partner, we provide consistent quality, inspection reports, and responsive customer support, making us a reliable choice for your custom CNC machining needs.

Request a Quote today and let us help you achieve precise, high-quality CNC parts for your projects.